The most common brazing filler metals are alloys based on silver, copper, nickel, and aluminum. These families of metals are selected for their ability to melt at a lower temperature than the base materials being joined, flow into the joint via capillary action, and form a strong, permanent metallurgical bond upon cooling.

The selection of a brazing filler metal is a critical engineering decision. It is not about finding a universal "glue," but about choosing a specific alloy whose chemical and thermal properties are precisely matched to the base metals and the performance demands of the final assembly.

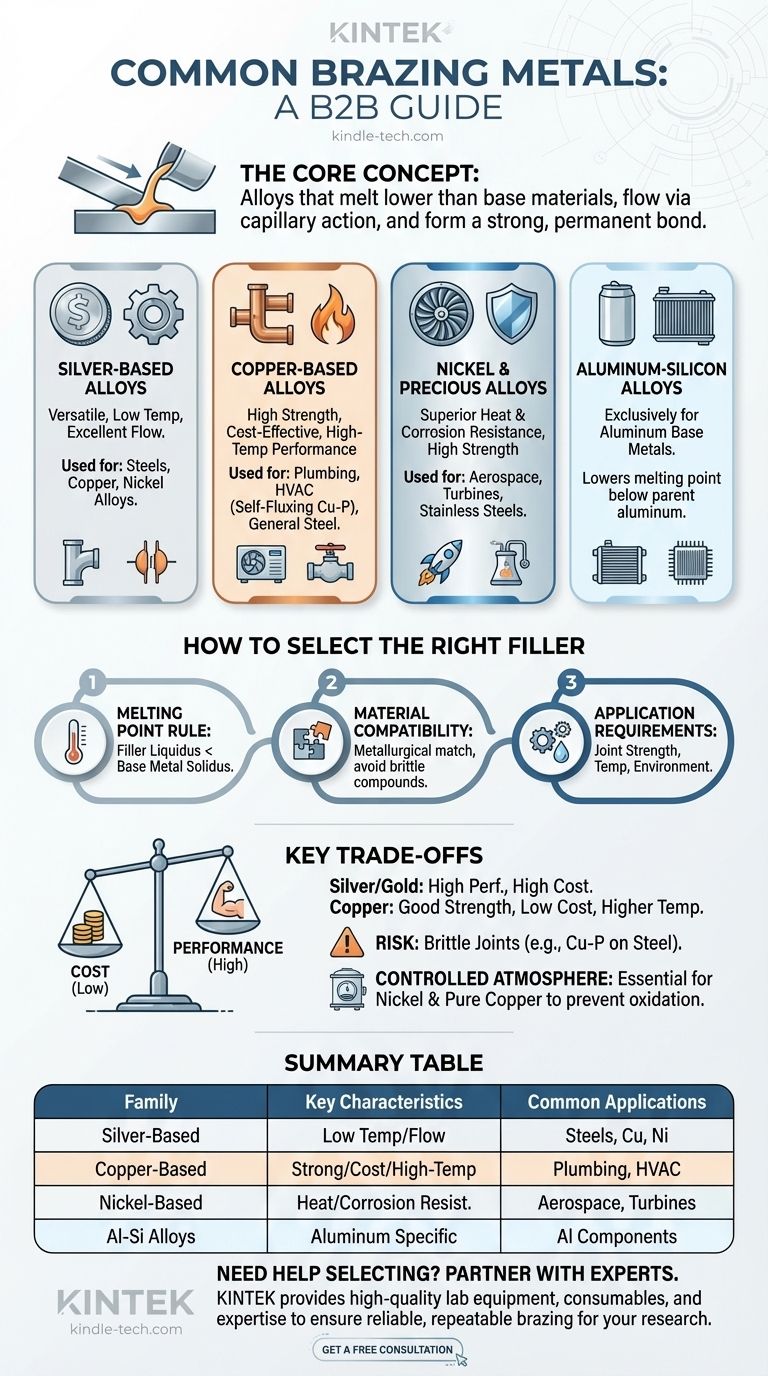

The Primary Families of Brazing Filler Metals

Brazing alloys are typically categorized by their primary metallic element. Each family offers a unique combination of melting temperature, strength, corrosion resistance, and cost.

Silver-Based Alloys

Silver alloys are some of the most versatile and widely used filler metals. They offer low brazing temperatures and excellent flow characteristics.

Common formulations include silver-copper, copper-silver-zinc, and other multi-component alloys. They are used extensively for joining steels, copper, and nickel alloys.

Copper-Based Alloys

Copper alloys are valued for their strength, high-temperature performance, and cost-effectiveness.

This family includes pure copper, copper-zinc (brass), copper-tin (bronze), and copper-phosphorus alloys. Copper-phosphorus fillers are notably "self-fluxing" when used on pure copper, making them a standard in the plumbing and HVAC industries.

Nickel and Precious Metal Alloys

Nickel alloys are the primary choice for applications requiring high strength and superior resistance to heat and corrosion.

These fillers, along with alloys containing palladium or gold, are essential for brazing stainless steels and superalloys in demanding environments like aerospace and turbine manufacturing.

Aluminum-Silicon Alloys

These specialized filler metals are used exclusively for brazing aluminum base metals.

The addition of silicon to the aluminum filler metal significantly lowers its melting point below that of the parent aluminum, enabling the brazing process to occur without melting the components being joined.

How to Select the Right Filler Metal

Choosing the correct filler metal depends on a few fundamental principles. Getting this wrong is the most common source of brazing failure.

The Melting Point Rule

The most critical rule of brazing is that the filler metal's melting temperature (liquidus) must be lower than the melting temperature of the base metals you are joining. This ensures the filler becomes liquid and flows while the base parts remain solid.

Material Compatibility

The filler metal must be metallurgically compatible with the base metals. An incompatible filler can fail to wet and flow into the joint or, worse, can form brittle intermetallic compounds that compromise the joint's integrity.

Application Requirements

The final service conditions dictate the choice. You must consider the required joint strength, the operating temperature of the final assembly, and any exposure to corrosive elements.

Understanding the Trade-offs

Every filler metal choice involves balancing performance with practicality. Understanding these compromises is key to a successful design.

Cost vs. Performance

There is a direct correlation between cost and performance. Silver and gold-based alloys offer exceptional performance but come at a high price. Copper alloys provide excellent strength for a much lower cost but require higher brazing temperatures.

The Risk of Brittle Joints

Certain filler-base metal combinations are notoriously problematic. For example, using a copper-phosphorus alloy to braze steel or other iron-based metals can create brittle iron phosphides at the joint interface, leading to catastrophic failure under stress.

The Need for a Controlled Atmosphere

Many high-performance filler metals, especially nickel and pure copper, oxidize rapidly when heated. These processes must be performed in a controlled atmosphere oven (like a vacuum or hydrogen environment) to protect the joint and ensure proper filler flow.

Making the Right Choice for Your Application

Your final selection should be driven by the specific materials you are joining and the environment the final product will endure.

- If your primary focus is general-purpose joining of steel, copper, or brass: Silver-based alloys are a versatile and reliable choice due to their low melting points and strong bonding characteristics.

- If your primary focus is joining copper to copper (e.g., HVAC tubing): Copper-phosphorus alloys are the industry standard for their self-fluxing properties and cost-effectiveness.

- If your primary focus is high-temperature strength and corrosion resistance: Nickel-based alloys are the definitive choice for applications like brazing stainless steel components for turbines or aerospace.

- If your primary focus is joining aluminum components: Aluminum-silicon alloys are the only suitable option, specifically designed to work with aluminum base metals.

Ultimately, choosing the right brazing metal is about matching its properties to the materials and demands of your specific engineering challenge.

Summary Table:

| Filler Metal Family | Key Characteristics | Common Applications |

|---|---|---|

| Silver-Based Alloys | Low brazing temperature, excellent flow | Joining steels, copper, nickel alloys |

| Copper-Based Alloys | High strength, cost-effective, high-temp performance | Plumbing, HVAC, general steel joining |

| Nickel-Based Alloys | Superior heat & corrosion resistance | Aerospace, turbines, stainless steels |

| Aluminum-Silicon Alloys | Specifically for aluminum base metals | Joining aluminum components |

Need Help Selecting the Right Brazing Metal for Your Lab's Application?

Choosing the correct brazing filler metal is critical for creating strong, reliable joints in your laboratory equipment and components. The wrong choice can lead to joint failure, compromising your research and development.

KINTEK specializes in providing high-quality lab equipment and consumables, including brazing materials and the furnaces needed for precise thermal processing. Our experts understand the material science behind brazing and can help you select the ideal alloy—whether it's a versatile silver-based filler for general use or a high-performance nickel alloy for demanding environments.

We can help you:

- Identify the perfect filler metal for your specific base materials and performance requirements.

- Source the necessary equipment, from standard furnaces to controlled atmosphere ovens for sensitive alloys.

- Ensure your brazing processes are reliable and repeatable, saving you time and resources.

Contact us today to discuss your project and let our expertise strengthen your laboratory's capabilities.

Get a Free Consultation on Your Brazing Needs

Visual Guide

Related Products

- Warm Isostatic Press for Solid State Battery Research

- Special Shape Press Mold for Lab

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Infrared Heating Quantitative Flat Plate Press Mold

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

People Also Ask

- What does HIP process do? Eliminate Porosity for Superior Material Performance

- What are the advantages and limitations of hot isostatic pressing? Achieve Ultimate Material Integrity

- What does hot isostatic pressing do? Eliminate Internal Flaws for Superior Part Performance

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance