The single greatest advantage of Selective Heat Sintering (SHS) is its ability to produce 3D printed parts without the need for any support structures. This fundamental difference from other printing methods unlocks significant benefits in design freedom, workflow efficiency, and part strength.

Selective Heat Sintering moves beyond simple prototyping by eliminating support structures. This allows engineers to create highly complex, functional parts with fewer design constraints and less post-processing, making it a powerful tool for both advanced prototyping and small-series production.

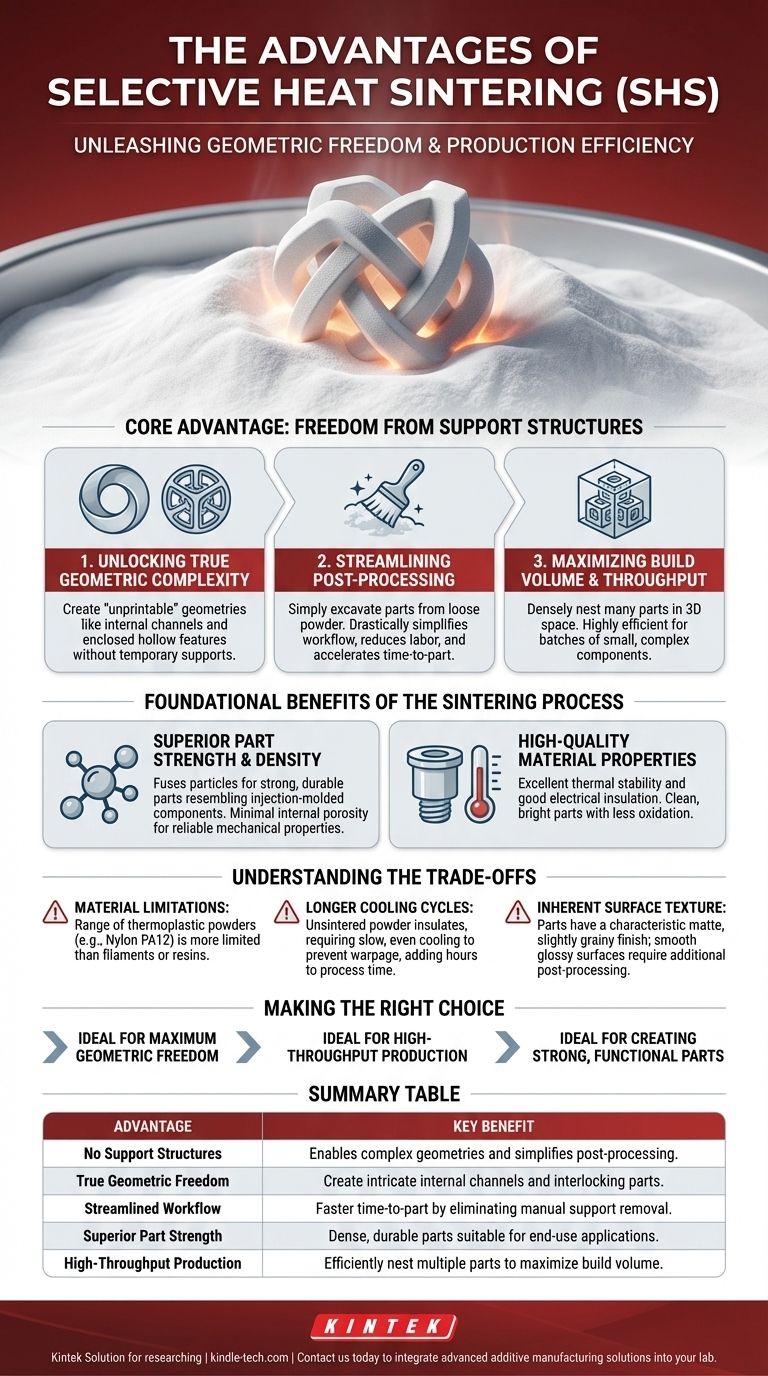

The Core Advantage: Freedom from Support Structures

The defining characteristic of SHS is that the unfused powder in the build chamber provides all the necessary support for the part as it's being printed. This seemingly simple fact has profound implications for the entire manufacturing process.

Unlocking True Geometric Complexity

Most 3D printing methods, like FDM or SLA, require you to design and print temporary supports for any overhangs or bridges. SHS completely removes this limitation.

This allows for the creation of previously "unprintable" geometries, such as intricate internal channels, fully enclosed hollow features, and complex, interlocking parts printed in a single assembly.

Streamlining the Post-Processing Workflow

Removing support structures is often a manual, time-consuming, and delicate process that can damage the part. With SHS, post-processing is drastically simplified.

Once the build is complete and cooled, the parts are simply excavated from the loose powder. This significantly reduces labor costs and accelerates the time from print to usable part.

Maximizing Build Volume and Throughput

Because no space is wasted on support structures, parts can be densely "nested" or packed together in all three dimensions within the build volume.

This ability to print many different parts simultaneously makes SHS highly efficient for producing batches of small, complex components, maximizing the productivity of each print job.

The Foundational Benefits of the Sintering Process

Beyond the lack of supports, the underlying physics of sintering—fusing thermoplastic powder particles together with heat—delivers robust parts suitable for demanding applications.

Superior Part Strength and Density

The sintering process creates strong bonds between material particles, resulting in parts with high strength and durability that closely resemble injection-molded components.

By fusing the powder, the process minimizes internal porosity. This leads to dense, solid parts with reliable mechanical properties, making them suitable for functional prototypes and end-use applications.

High-Quality Material Properties

Sintering creates parts with excellent thermal stability and, depending on the material, good electrical insulation. This makes it a viable process for components that must perform under real-world conditions.

The process also produces parts that are clean and bright, with less oxidation compared to some other thermal manufacturing techniques.

Understanding the Trade-offs

No technology is perfect. To make an informed decision, it's critical to understand the limitations of Selective Heat Sintering.

Material Limitations

Currently, SHS technology primarily works with a specific range of thermoplastic powders, most commonly Nylon (PA12). While these materials are versatile and robust, the selection is more limited compared to the vast array of filaments or resins available for other processes.

Longer Cooling Cycles

The unsintered powder that supports the part also acts as an excellent insulator. Consequently, the entire block of powder must cool down slowly and evenly to prevent part warpage. This cooling period can add several hours to the total process time.

Inherent Surface Texture

Parts made with SHS have a characteristic matte, slightly grainy surface finish due to the nature of the fused powder particles. While this is suitable for many applications, achieving a perfectly smooth, glossy surface requires additional post-processing steps like polishing or coating.

Making the Right Choice for Your Goal

SHS is a powerful tool when applied to the right problem. Use these guidelines to determine if it fits your needs.

- If your primary focus is maximum geometric freedom: SHS is the superior choice for creating parts with internal channels, captive components, or other complex features that are impossible to produce with support-based methods.

- If your primary focus is high-throughput production: The ability to nest dozens or hundreds of small parts in a single build makes SHS exceptionally efficient for small-series manufacturing runs.

- If your primary focus is creating strong, functional parts: SHS produces durable, end-use components with reliable mechanical properties that go far beyond the capability of typical brittle prototypes.

By understanding its unique ability to fuse strength with complexity, you can leverage Selective Heat Sintering to solve significant engineering challenges.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| No Support Structures | Enables complex geometries and simplifies post-processing. |

| True Geometric Freedom | Create intricate internal channels and interlocking parts. |

| Streamlined Workflow | Faster time-to-part by eliminating manual support removal. |

| Superior Part Strength | Dense, durable parts suitable for end-use applications. |

| High-Throughput Production | Efficiently nest multiple parts to maximize build volume. |

Ready to leverage the power of support-free 3D printing for your lab's prototyping and production needs?

At KINTEK, we specialize in providing advanced lab equipment and consumables, including solutions for additive manufacturing. Our expertise can help you integrate technologies like Selective Heat Sintering to enhance your design freedom and accelerate innovation.

Contact us today to discuss how we can support your laboratory's specific requirements with the right equipment and materials.

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Three-dimensional electromagnetic sieving instrument

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Laboratory Hybrid Tissue Grinding Mill

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What role does a hot press play in treating the CAL-GPE interface? Optimize Performance for Flexible Lithium Batteries

- What role does a laboratory plate hot press play in the vulcanization and molding of fluorosilicone rubber (F-LSR)?

- What are the advantages of using a hot press for Li7P2S8I0.5Cl0.5? Boost Conductivity with Precision Densification

- What is a hydraulic floor press used for? A Versatile Tool for Industrial and Lab Applications

- Why is a laboratory hot press necessary for the production of plastic crystal polymer electrolyte reinforced membranes?