At its core, heat treating steel is a highly controlled process of heating and cooling to deliberately alter the metal’s physical and mechanical properties. The primary methods include annealing, quenching, tempering, and case hardening, each designed to achieve a specific outcome, such as increasing hardness, improving toughness, or making the steel easier to machine.

The specific heat treatment method you choose is not about finding the "best" one, but about selecting the precise thermal cycle—heating, holding, and cooling—that will engineer the steel's internal structure to match the demands of its final application.

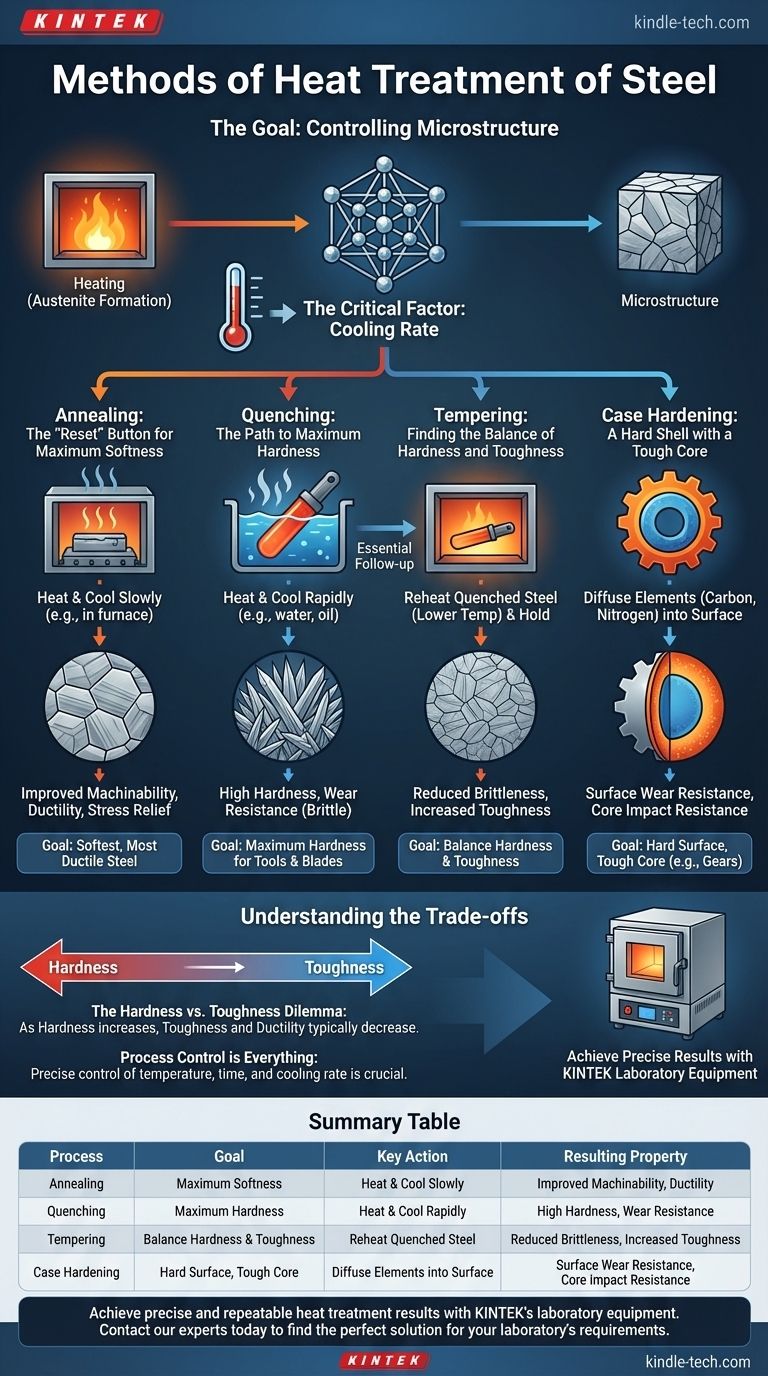

The Goal of Heat Treatment: Controlling Microstructure

The properties of a steel part are determined by its internal crystal structure, known as its microstructure. Heat treatment is the tool used to manipulate this structure.

The Role of Temperature

Heating steel to a high temperature (typically above 723°C or 1333°F) dissolves carbon into the iron matrix, creating a structure called austenite. This phase is the necessary starting point for most heat treatments.

The Critical Factor: Cooling Rate

The final properties of the steel are almost entirely dictated by how quickly it is cooled from its austenitic state. The rate of cooling determines which microstructure forms, locking in properties like hardness and strength.

Core Heat Treatment Processes

Each primary process uses a different cooling strategy to achieve a distinct result. Think of them as different paths leading to different destinations.

Annealing: The "Reset" Button for Maximum Softness

The goal of annealing is to produce the softest, most ductile, and most machinable version of a steel. It is used to relieve internal stresses that may have built up during manufacturing.

The process involves heating the steel, holding it at temperature to ensure uniformity, and then cooling it as slowly as possible, often by leaving it inside the turned-off furnace. This slow cooling allows a soft, coarse microstructure called pearlite to form.

Quenching: The Path to Maximum Hardness

Quenching is performed to make steel as hard as possible. It is the foundational process for making tools, blades, and wear-resistant components.

This process involves heating the steel to form austenite and then cooling it extremely rapidly. This is done by submerging the hot part in a medium like water, oil, or even forced air. This "thermal shock" traps the steel's carbon in a very hard but brittle structure called martensite.

Tempering: Finding the Balance of Hardness and Toughness

A part that has been quenched is extremely hard, but it is also very brittle and susceptible to shattering. Tempering is the essential follow-up process to reduce this brittleness.

Tempering involves reheating the hardened (quenched) steel to a much lower temperature (e.g., 200-600°C or 400-1100°F) and holding it for a set time. This process sacrifices a small amount of hardness to gain a significant increase in toughness—the material's ability to absorb energy and resist fracturing.

Specialized Surface Treatments

Sometimes, you don't need the entire part to be hard. You only need a hard surface for wear resistance, while keeping the inside of the part tough to handle impact.

Case Hardening: A Hard Shell with a Tough Core

Case hardening is a group of processes that modify only the surface chemistry of the steel. This creates a "case" of high hardness around a softer, tougher "core."

Processes like carburizing (adding carbon) or nitriding (adding nitrogen) diffuse these elements into the surface layer. The part is then typically quenched and tempered. This is ideal for components like gears and bearings, which must resist surface wear while also withstanding shock loads.

Understanding the Trade-offs

Choosing a heat treatment process is always an exercise in balancing competing properties. There is no single treatment that maximizes all desirable characteristics.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off in steel heat treatment. As you increase a steel's hardness, you almost always decrease its toughness and ductility.

- Fully annealed steel is very tough and ductile but soft.

- Fully quenched steel is extremely hard but very brittle.

- Tempered steel sits on a spectrum between these two extremes. Higher tempering temperatures result in softer, tougher steel; lower temperatures result in harder, less tough steel.

Process Control is Everything

The success of any heat treatment depends on precise control of temperature, time, and cooling rate. Minor deviations can result in cracking, warping, or a complete failure to achieve the desired microstructure.

Specialized equipment, such as the muffle furnaces used for testing, provides the tight thermal control needed to ensure these processes are repeatable and reliable.

Selecting the Right Process for Your Goal

Your choice must be driven by the specific requirements of the finished part.

- If your primary focus is to prepare steel for machining or forming: Use annealing to make the material as soft and workable as possible.

- If your primary focus is maximum hardness and wear resistance: Use quenching, but be aware that the part will be brittle and likely requires a subsequent step.

- If your primary focus is a durable part that is both hard and tough: Use quenching followed by tempering to dial in the precise balance needed for the application.

- If your primary focus is a wear-resistant surface on a part that must absorb shock: Use a case hardening process to create a hard exterior with a tough, ductile core.

Understanding these core processes transforms heat treatment from a set of abstract recipes into a powerful tool for engineering steel to your exact specifications.

Summary Table:

| Process | Goal | Key Action | Resulting Property |

|---|---|---|---|

| Annealing | Maximum Softness | Heat & Cool Slowly | Improved Machinability, Ductility |

| Quenching | Maximum Hardness | Heat & Cool Rapidly | High Hardness, Wear Resistance |

| Tempering | Balance Hardness & Toughness | Reheat Quenched Steel | Reduced Brittleness, Increased Toughness |

| Case Hardening | Hard Surface, Tough Core | Diffuse Elements into Surface | Surface Wear Resistance, Core Impact Resistance |

Achieve precise and repeatable heat treatment results with KINTEK's laboratory equipment.

The success of processes like annealing, quenching, and tempering depends on exact control over temperature and cooling rates. KINTEK specializes in high-quality lab furnaces, including muffle furnaces, that provide the reliable thermal performance your R&D or quality control lab needs.

Whether you are developing new alloys or ensuring product consistency, our equipment helps you engineer steel properties with confidence.

Contact our experts today to find the perfect heat treatment solution for your laboratory's requirements.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the relationship between sintering temperature and melting temperature? Key Differences for Material Engineers

- What is the meaning of debinding? Master the Critical Step to High-Performance Parts

- What are the 4 types of heat treatment steel undergoes? Master Annealing, Normalizing, Hardening & Tempering

- What is the function of a muffle furnace? Achieve Pure, Contamination-Free Heating

- What is the yield of biochar in slow pyrolysis? Maximize Your Output Up to 30%