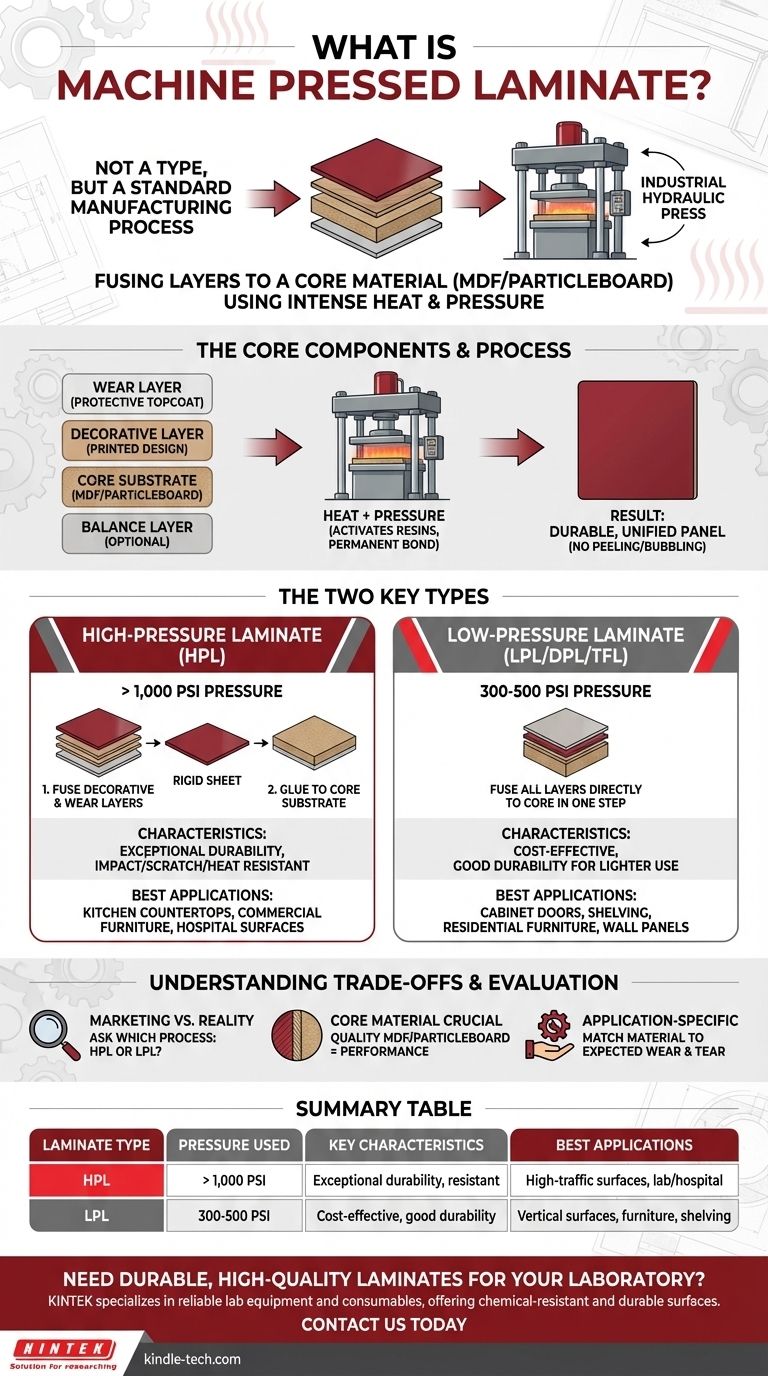

In short, "machine pressed laminate" is not a specific type of laminate, but rather a description of the standard manufacturing process. It refers to any laminate product where layers of paper or plastic are fused to a core material—typically Medium-Density Fiberboard (MDF) or particleboard—using industrial machinery that applies intense heat and pressure. This process creates a permanent, durable bond that is the basis for virtually all modern laminate furniture, flooring, and cabinetry.

The term "machine pressed" is a marketing phrase that describes the universal method for making laminate products. The true factors that determine quality are the specific type of laminate process used (High-Pressure vs. Low-Pressure) and the quality of the underlying core material.

The Manufacturing Process Explained

To understand the value of a machine pressed product, you must first understand its components and how they are assembled. This process turns simple raw materials into a durable, decorative surface.

The Core Components

All laminate panels consist of a few key layers. The machine's job is to fuse them into one.

The substrate, or core board, provides the structure. This is almost always a composite wood product like MDF or particleboard.

The decorative layer is a high-resolution printed paper that gives the laminate its appearance, such as a wood grain or stone pattern.

The wear layer is a clear, protective topcoat, often containing melamine resin, that provides resistance to scratches, stains, and heat.

The Role of Heat and Pressure

The "press" in the name is the critical step. The assembled layers are placed in a large hydraulic press that applies hundreds of pounds per square inch (PSI) of pressure at high temperatures.

This combination of heat and pressure activates the resins within the layers, permanently bonding them to each other and to the substrate. This creates a single, stable, and solid panel.

Why This Method is Standard

This industrial process is the standard because it ensures a strong, consistent bond across the entire surface. It prevents common defects like bubbling, peeling, or delamination that would occur with less sophisticated adhesive methods.

The Two Key Types of Machine Pressed Laminate

While "machine pressed" is a general term, it covers two distinct manufacturing processes. The difference between them is the primary indicator of a product's durability and intended use.

High-Pressure Laminate (HPL)

In the HPL process, the decorative and wear layers are first fused together under extreme pressure (often over 1,000 PSI) and heat to form a rigid sheet. This separate, durable sheet is then glued to the core substrate in a secondary step.

This multi-step process makes HPL exceptionally durable. It is highly resistant to impact, scratches, and heat, making it the standard choice for high-wear surfaces like kitchen countertops, commercial tables, and hospital furniture.

Low-Pressure Laminate (LPL)

Also known as Direct-Pressure Laminate (DPL) or Thermally Fused Laminate (TFL), this method is more direct. The decorative and wear layers are placed directly onto the substrate and fused in a single step using lower pressure (around 300-500 PSI) and heat.

LPL is less impact-resistant than HPL but is still very durable for its intended applications. It is a cost-effective solution for vertical or low-traffic surfaces like cabinet doors, shelving, closet organizers, and residential furniture.

Understanding the Trade-offs

Marketers often use the term "machine pressed" to imply a high-quality, automated process, which is true. However, it doesn't tell you the whole story.

Marketing vs. Reality

Nearly all laminate is machine pressed. Knowing this tells you very little about its quality. You must ask which machine pressing process was used (HPL or LPL) to truly understand what you are buying.

The Core Material is Crucial

The world's best laminate surface is only as good as the board it's bonded to. A high-density particleboard or moisture-resistant MDF will perform significantly better than a low-density, standard-grade core, especially in demanding environments. A weak core can be damaged by moisture or impact, causing the laminate to fail.

Durability is Application-Specific

There is no "bad" choice between HPL and LPL, only an inappropriate one. Using LPL for a kitchen countertop will lead to premature failure, while using expensive HPL for a closet interior is often unnecessary. The key is to match the material to the expected wear and tear.

How to Evaluate a "Machine Pressed" Product

When you encounter this term, use it as a starting point to ask more specific questions. Focus on the underlying construction rather than the general marketing phrase.

- If your primary focus is maximum durability for high-traffic surfaces (countertops, desks): Ask specifically for High-Pressure Laminate (HPL) and inquire about the density of the particleboard or MDF core.

- If your primary focus is affordable aesthetics for lighter use (cabinet doors, shelving, wall panels): Low-Pressure Laminate (LPL/TFL) is an excellent, cost-effective choice that offers a huge range of decorative options.

- If your primary focus is moisture resistance (kitchens, bathrooms): Prioritize a product built on a moisture-resistant (MR) grade core, as this is the most critical factor for longevity in damp environments.

Ultimately, understanding the details behind the term "machine pressed" allows you to look past the label and assess the true quality and suitability of the product for your specific needs.

Summary Table:

| Laminate Type | Pressure Used | Key Characteristics | Best Applications |

|---|---|---|---|

| High-Pressure Laminate (HPL) | > 1,000 PSI | Exceptional durability, impact/scratch/heat resistant | Kitchen countertops, commercial furniture, hospital surfaces |

| Low-Pressure Laminate (LPL/DPL) | 300-500 PSI | Cost-effective, good durability for lighter use | Cabinet doors, shelving, residential furniture, wall panels |

Need Durable, High-Quality Laminates for Your Laboratory?

KINTEK specializes in lab equipment and consumables, providing reliable surfaces that withstand demanding environments. Whether you need chemical-resistant countertops, durable cabinet surfaces, or specialized furniture for your lab, our expertise ensures you get the right laminate solution for your specific requirements.

Contact us today to discuss your project and discover how our solutions can enhance your lab's functionality and longevity. Get in touch with our experts →

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What role does a hot press play in treating the CAL-GPE interface? Optimize Performance for Flexible Lithium Batteries

- What role does a laboratory plate hot press play in the vulcanization and molding of fluorosilicone rubber (F-LSR)?

- Why is a laboratory hot press required for Oxygen Depolarized Cathodes? Ensure Precision Molding and Conductivity.

- What is a hydraulic floor press used for? A Versatile Tool for Industrial and Lab Applications

- Why is a laboratory precision hot press necessary for processing high-performance composite solid-state electrolyte membranes?