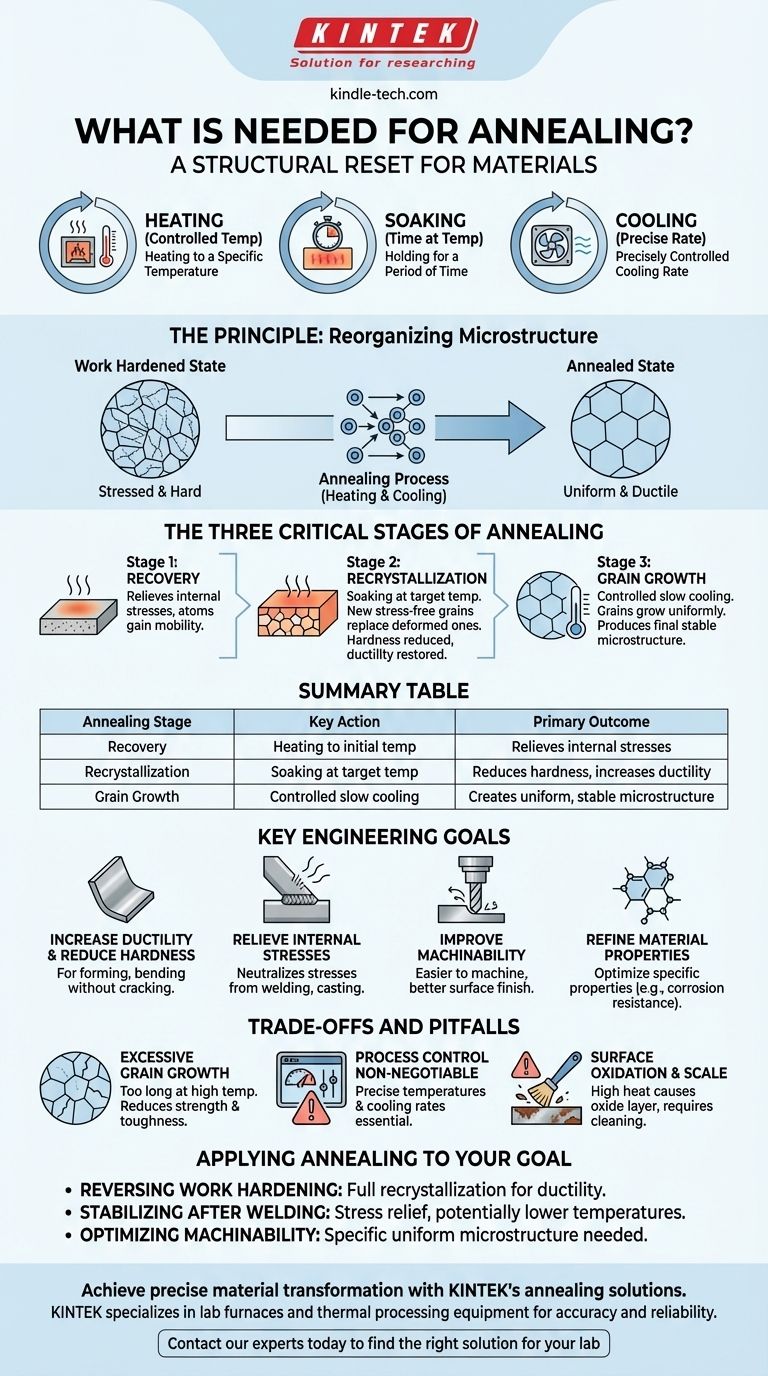

At its core, annealing requires three critical elements: a method for heating a material to a specific temperature, a period of time to hold it there, and a precisely controlled rate of cooling. This thermal treatment is not simply about heating and cooling; it is a deliberate process designed to fundamentally alter a material's internal microstructure. The primary goal is to relieve internal stresses, reduce hardness, and increase ductility, making the material more uniform and easier to work with.

The essential truth of annealing is that it is a structural reset for a material. By carefully applying heat and controlling the cooling rate, you erase the microscopic defects and stresses introduced by processes like welding, casting, or cold forming, resulting in a softer, more stable, and more workable metal.

The Principle: Reorganizing a Metal's Microstructure

To understand annealing, you must think of metal not as a static solid, but as a crystalline structure. Manufacturing processes can stretch, compress, and disorganize these crystals, introducing internal stress and making the material hard and brittle—a state known as work hardening.

Annealing systematically reverses this damage. It provides enough thermal energy for the atoms within the crystal lattice to rearrange themselves into a more uniform and lower-stress state.

The Three Critical Stages of Annealing

The process is a carefully managed sequence. Each stage serves a distinct purpose in transforming the material's properties from a stressed state to a stable one.

Stage 1: Recovery

As the material is heated, the first stage is recovery. During this phase, the material begins to relieve some of its internal stresses as the atoms gain mobility from the thermal energy.

Stage 2: Recrystallization

This is the most critical stage. The material is heated to its recrystallization temperature and held there, a process often called "soaking." At this temperature, new, stress-free crystal grains begin to nucleate and grow, systematically replacing the deformed grains created during fabrication. This is where the material's hardness is significantly reduced and its ductility is restored.

Stage 3: Grain Growth

After the material has fully recrystallized, the final stage involves controlled, slow cooling. This slow pace is essential. It prevents the formation of new internal stresses and allows the newly formed grains to grow in a uniform, homogeneous way, producing the final desired microstructure.

Key Engineering Goals of Annealing

Annealing is not performed arbitrarily; it is specified to achieve clear, measurable engineering outcomes that improve a component's performance or manufacturability.

To Increase Ductility and Reduce Hardness

The most common reason to anneal is to reverse the effects of work hardening. By making the material softer and more ductile, it can undergo further forming, bending, or drawing without cracking.

To Relieve Internal Stresses

Processes like welding and casting leave behind significant residual stresses. These stresses can act as failure points, leading to cracking or distortion over time. Annealing neutralizes these stresses, creating a more stable and reliable component.

To Improve Machinability

A material with a uniform, soft internal structure is far easier to machine accurately. Annealing creates this consistency, reducing tool wear and improving the final surface finish.

To Refine Material Properties

For certain alloys, annealing serves specialized purposes. For example, solution annealing in 300 series stainless steels is used specifically to improve corrosion resistance by dissolving chromium carbides back into the crystalline matrix.

Understanding the Trade-offs and Pitfalls

While powerful, annealing is a process of precision. A lack of control can lead to undesirable results.

The Risk of Excessive Grain Growth

If a material is held at temperature for too long or heated to an excessive temperature, the crystal grains can grow too large. Overly large grains can actually reduce the material's strength and toughness.

Process Control is Non-Negotiable

The success of annealing depends entirely on hitting the correct temperatures and cooling rates for the specific alloy being treated. Using generic parameters is a common cause of failure, resulting in a part that does not meet its required mechanical properties.

Surface Oxidation and Scale

Heating metals to high temperatures can cause a layer of oxide, or scale, to form on the surface. This is a common side effect that may require a secondary cleaning process, like pickling or abrasive blasting, to remove.

Applying Annealing to Your Goal

The right approach depends entirely on your objective for the material.

- If your primary focus is reversing work hardening: The key is ensuring the material reaches its full recrystallization temperature to restore ductility for further forming operations.

- If your primary focus is stabilizing a part after welding or casting: The goal is stress relief, which may sometimes be achieved at temperatures below full recrystallization, saving time and energy.

- If your primary focus is optimizing for machinability: You need a process that produces a specific, uniform microstructure known to be ideal for cutting, which requires strict adherence to proven temperature and cooling profiles.

Ultimately, understanding the needs of your material is the first step toward leveraging this fundamental metallurgical process.

Summary Table:

| Annealing Stage | Key Action | Primary Outcome |

|---|---|---|

| Recovery | Heating to initial temperature | Relieves internal stresses |

| Recrystallization | Soaking at target temperature | Reduces hardness, increases ductility |

| Grain Growth | Controlled slow cooling | Creates uniform, stable microstructure |

Achieve precise material transformation with KINTEK's annealing solutions.

Whether you need to reverse work hardening, relieve stress from welding, or optimize machinability, precise temperature control is non-negotiable. KINTEK specializes in lab furnaces and thermal processing equipment that deliver the accuracy and reliability your laboratory requires.

Our expertise in lab equipment ensures you can achieve the perfect microstructure for your specific alloy and application goals. Let's discuss your annealing needs and enhance your material properties.

Contact our experts today to find the right solution for your lab

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the purpose of inert atmosphere? A Guide to Protecting Your Materials and Processes

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes

- How does an atmosphere furnace facilitate the post-treatment of nickel-plated carbon fibers? Ensure Peak Bonding

- What gases are used in inert atmospheres? Choose the Right Gas for Non-Reactive Environments

- What is an example of an inert atmosphere? Discover the Best Gas for Your Process