The cost of lining a furnace flue ranges from as little as $10 per square foot for basic materials to over $65 per square foot for high-performance systems. However, the material cost is only one component. The final price depends heavily on the type of furnace you have, the condition of your chimney, and the complexity of the installation.

The central challenge is not finding the cheapest material, but selecting the correct liner for your specific furnace and chimney. An improperly matched liner can lead to inefficiency, premature failure, and significant safety hazards.

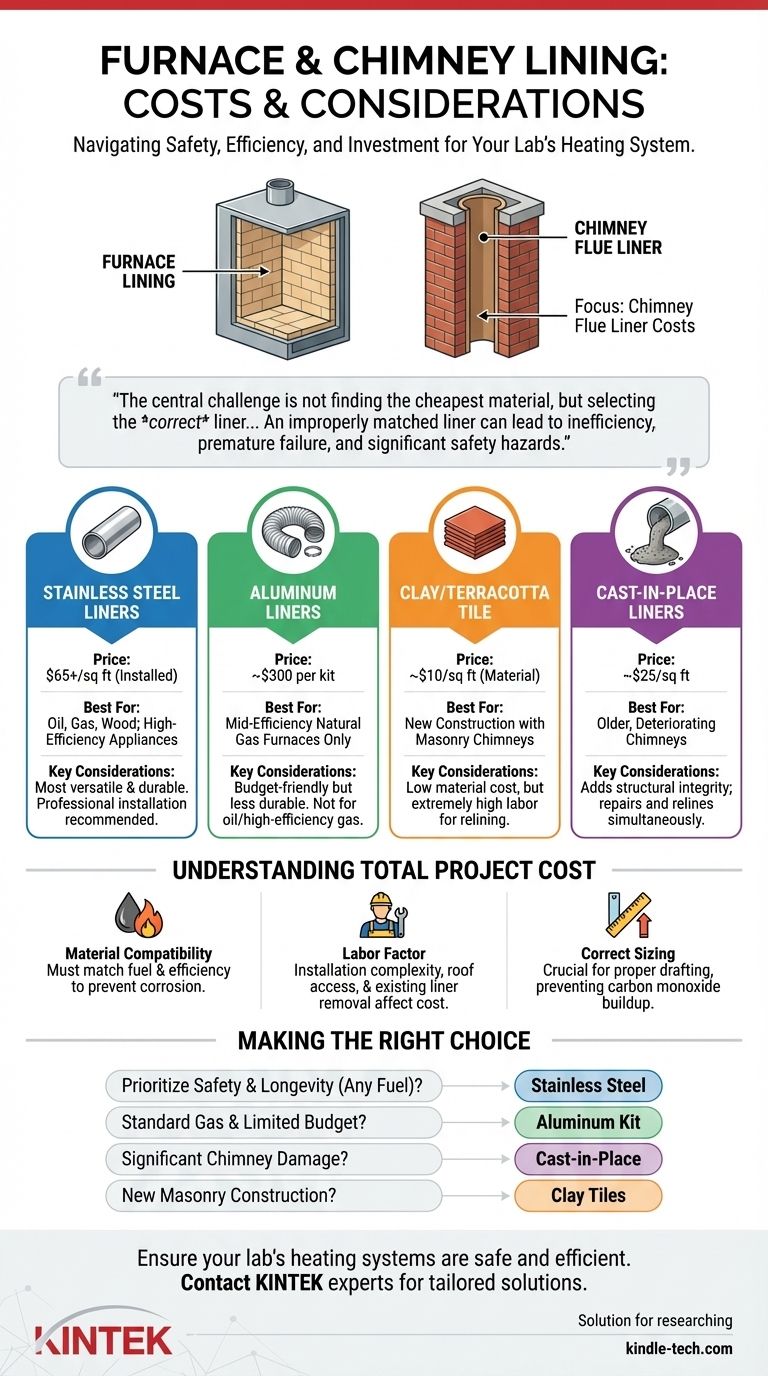

Clarifying Terms: Furnace Lining vs. Chimney Lining

When discussing furnace lining costs, it's crucial to distinguish between two different components. Most people are referring to the chimney flue liner, which is the tube inside your chimney that vents exhaust gases safely outside.

The furnace itself also has an internal lining in its combustion chamber, typically made of refractory materials, but this is a separate component. The costs discussed here refer to the chimney flue liner that serves your furnace.

A Breakdown of Chimney Liner Costs and Materials

The material you choose is the primary driver of cost. Each type has a specific application and price point.

Stainless Steel Liners

A rigid or flexible stainless steel tube is the most common and versatile relining solution. It is suitable for furnaces that use oil, gas, or wood.

The quoted cost of $65 per square foot often reflects a professional installation, as the material itself is less expensive. This is the required choice for modern, high-efficiency appliances.

Aluminum Liners

Aluminum is a more economical but less durable option, typically sold in kits. It is a lightweight, flexible material that is easier to install.

At around $300 per kit, aluminum is a budget-friendly choice, but it is only suitable for certain mid-efficiency natural gas furnaces. It cannot withstand the corrosive byproducts of oil or high-efficiency gas furnaces.

Clay/Terracotta Tile Liners

This is the traditional material used when building a masonry chimney. The tiles are stacked on top of each other to form the flue.

While the material cost is low at $10 per square foot, it is extremely labor-intensive to install or repair. It is rarely used for relining an existing chimney and is typically only installed during new construction.

Cast-in-Place Liners

This method involves pouring a specialized, cement-like slurry down the chimney around a former to create a seamless, new flue.

At roughly $25 per square foot, this method is an excellent solution for older, deteriorating chimneys as it both relines the flue and adds significant structural integrity.

Understanding the Trade-offs and Total Project Cost

The material price is just the starting point. Several other factors will determine the final cost of your project.

The Pitfall of Material Cost Alone

Choosing the cheapest option, like an aluminum liner for an oil furnace, will lead to rapid corrosion and failure. The liner material must be compatible with the fuel type and efficiency of your appliance to ensure safety and longevity.

Labor is a Major Factor

Professional installation is a significant part of the total cost. Factors that increase labor include difficult roof access, a very tall chimney, or the need to remove an old, damaged liner.

The Importance of Correct Sizing

A liner must be sized correctly for the furnace it serves. An improperly sized liner can cause poor drafting, leading to a dangerous buildup of carbon monoxide or corrosive condensation that can destroy the liner and chimney. This is not a DIY project for the inexperienced.

Making the Right Choice for Your System

Your decision should be guided by your heating system's requirements and your long-term goals.

- If your primary focus is safety and longevity for any fuel type: A professionally installed stainless steel liner is the most reliable and versatile choice.

- If you have a standard-efficiency gas furnace and a limited budget: An aluminum liner kit can be a viable, cost-effective solution.

- If your chimney has significant cracks or masonry damage: A cast-in-place liner is a superior option that repairs and relines the flue simultaneously.

- If you are building a new home with a masonry chimney: Traditional clay tiles are a standard and effective, if labor-intensive, choice.

Ultimately, investing in the correct liner is a critical component of your heating system's safety, efficiency, and durability.

Summary Table:

| Material | Typical Cost (per sq ft) | Best For | Key Considerations |

|---|---|---|---|

| Stainless Steel | $65+ (installed) | Oil, gas, or wood furnaces; high-efficiency appliances | Most versatile and durable; professional installation recommended |

| Aluminum | ~$300 per kit | Mid-efficiency natural gas furnaces only | Budget-friendly but not suitable for oil or high-efficiency gas |

| Clay/Terracotta | ~$10 | New construction with masonry chimneys | Low material cost, but extremely high labor cost for relining |

| Cast-in-Place | ~$25 | Older, deteriorating chimneys needing structural repair | Adds structural integrity; repairs and relines simultaneously |

Ensure your lab's heating systems are safe and efficient with the right chimney liner.

Choosing the correct liner is critical for safety and performance. KINTEK specializes in lab equipment and consumables, including support for the systems that power your research. Our expertise can help you select the ideal components for your specific furnace and chimney setup.

Contact our experts today to discuss your needs and get a tailored solution for your laboratory.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between pyrolysis combustion and gasification? A Guide to Thermal Conversion Technologies

- How do high-temperature reaction furnaces control in-situ MMCs? Master Material Precision and Structural Integrity

- What are the equipment requirements for loading platinum (Pt) onto composite supports? Precise Stirring for High Dispersion

- What is the range of pyrolysis? Master Temperature Control for Optimal Bio-Product Yields

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity