The primary refractory material in a muffle furnace is a high-temperature ceramic, most commonly alumina (aluminum oxide). This material is used for both the dense inner chamber (the "muffle") and the lightweight insulating fibers that surround it, creating a system designed for extreme heat containment and chemical resistance.

A muffle furnace is not built from a single refractory material, but a system of them. A dense ceramic like alumina forms the durable inner chamber for processing materials, while lightweight alumina ceramic fiber provides the critical thermal insulation to contain the heat.

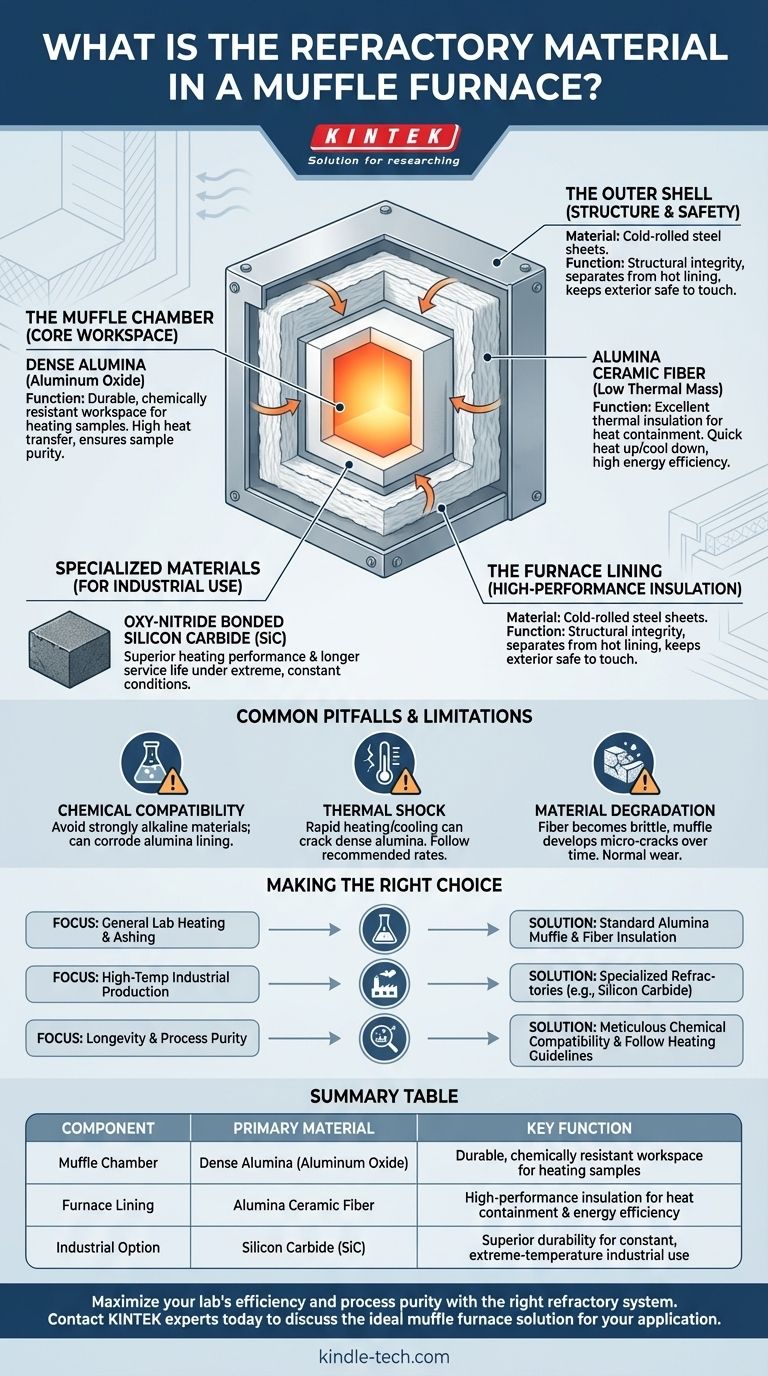

The Anatomy of a Muffle Furnace's Refractory System

To understand the materials, you must first understand the distinct components of the furnace and the specific job each performs. The "refractory" is not one part, but several layers working together.

The Muffle Chamber: The Core Workspace

The muffle itself is the sealed inner chamber where the heating takes place. It must be durable, stable, and capable of transferring heat evenly.

The material of choice here is typically a dense, solid ceramic like alumina. This is because it provides exceptional resistance to high temperatures and chemical attack, ensuring the purity of the samples being processed.

The Furnace Lining: High-Performance Insulation

Surrounding the muffle chamber is a thick lining of insulation. This is the most critical part for heat containment and energy efficiency.

This lining is almost always made from a lightweight, low-density material like high-purity alumina fiber (also known as ceramic fiber). This material is often vacuum-formed into boards or used as a soft blanket.

Its primary benefit is its excellent thermal insulation performance coupled with a very low thermal mass. This allows the furnace to heat up and cool down relatively quickly without storing a large amount of heat, improving efficiency and cycle times.

Specialized Materials for Industrial Use

For highly demanding industrial applications, such as the production of Zinc Oxide, more advanced refractories may be used.

Materials like oxy-nitride bonded silicon carbide (SiC) offer superior heating performance and a longer service life under constant, extreme conditions compared to standard alumina.

The Outer Shell: Structure and Safety

The exterior of the furnace is not a refractory material. It is typically constructed from cold-rolled steel sheets.

This shell provides the structural integrity for the unit. It is separated from the hot furnace lining by insulation, keeping the exterior safe to touch during operation.

Common Pitfalls and Material Limitations

Even the best refractory materials have limits. Understanding these is key to maximizing the furnace's lifespan and ensuring accurate results.

Chemical Compatibility

Refractory ceramics are resistant, but not indestructible. Strongly alkaline materials, for example, should not be heated inside the furnace as they can chemically attack and corrode the alumina lining over time.

Thermal Shock

Dense ceramics like the alumina muffle can crack if subjected to thermal shock—heating or cooling too rapidly. While the surrounding fiber insulation is highly resistant, the core chamber is more vulnerable. Always adhere to recommended heating and cooling rates.

Material Degradation

Over hundreds of cycles, the ceramic fiber insulation can become brittle and may begin to shed particles. The dense muffle can also develop micro-cracks from repeated expansion and contraction. This is normal wear, but it's a factor in the long-term service life of the furnace.

Making the Right Choice for Your Application

The specific refractory composition you need depends entirely on your goal.

- If your primary focus is general laboratory heating and ashing: A standard furnace with a high-purity alumina muffle and alumina fiber insulation is the industry-standard solution.

- If your primary focus is high-temperature industrial production: Consider a furnace with specialized refractories like silicon carbide for superior durability and a longer service life under constant use.

- If your primary focus is longevity and process purity: Be meticulous about chemical compatibility and follow the manufacturer's guidelines on heating rates to avoid thermal shock and premature degradation.

Understanding the materials inside your furnace empowers you to use it more effectively and extend its operational life.

Summary Table:

| Component | Primary Material | Key Function |

|---|---|---|

| Muffle Chamber | Dense Alumina (Aluminum Oxide) | Durable, chemically resistant workspace for heating samples |

| Furnace Lining | Alumina Ceramic Fiber | High-performance insulation for heat containment and energy efficiency |

| Industrial Option | Silicon Carbide (SiC) | Superior durability for constant, extreme-temperature industrial use |

Maximize your lab's efficiency and process purity with the right refractory system. The materials inside your muffle furnace are critical to its performance and lifespan. Whether your application requires standard alumina for laboratory ashing or industrial-grade silicon carbide for demanding production, KINTEK has the expertise and equipment to meet your specific laboratory needs.

Contact our experts today to discuss the ideal muffle furnace refractory solution for your application.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How is a high-temperature muffle furnace utilized when testing fire resistance of geopolymers? Ensure Material Safety

- What is another name for a muffle furnace? Understanding the Core Principle of Isolated Heating

- How does a high-temperature muffle furnace influence Zirconia thin films? Master Crystal Structure Evolution

- Why is a high-precision high-temperature furnace required for photosensitive glass? Master Controlled Crystallization

- What type of insulation is used in a muffle furnace? Essential Materials for High-Temperature Performance

- What precautions should be taken when using oven in laboratory? Ensure Your Lab's Safety and Efficiency

- What is the heating mechanism of a muffle furnace? Achieve Clean, Uniform High-Temperature Processing

- What is the calibration frequency of a muffle furnace? A Risk-Based Guide to Ensure Precision