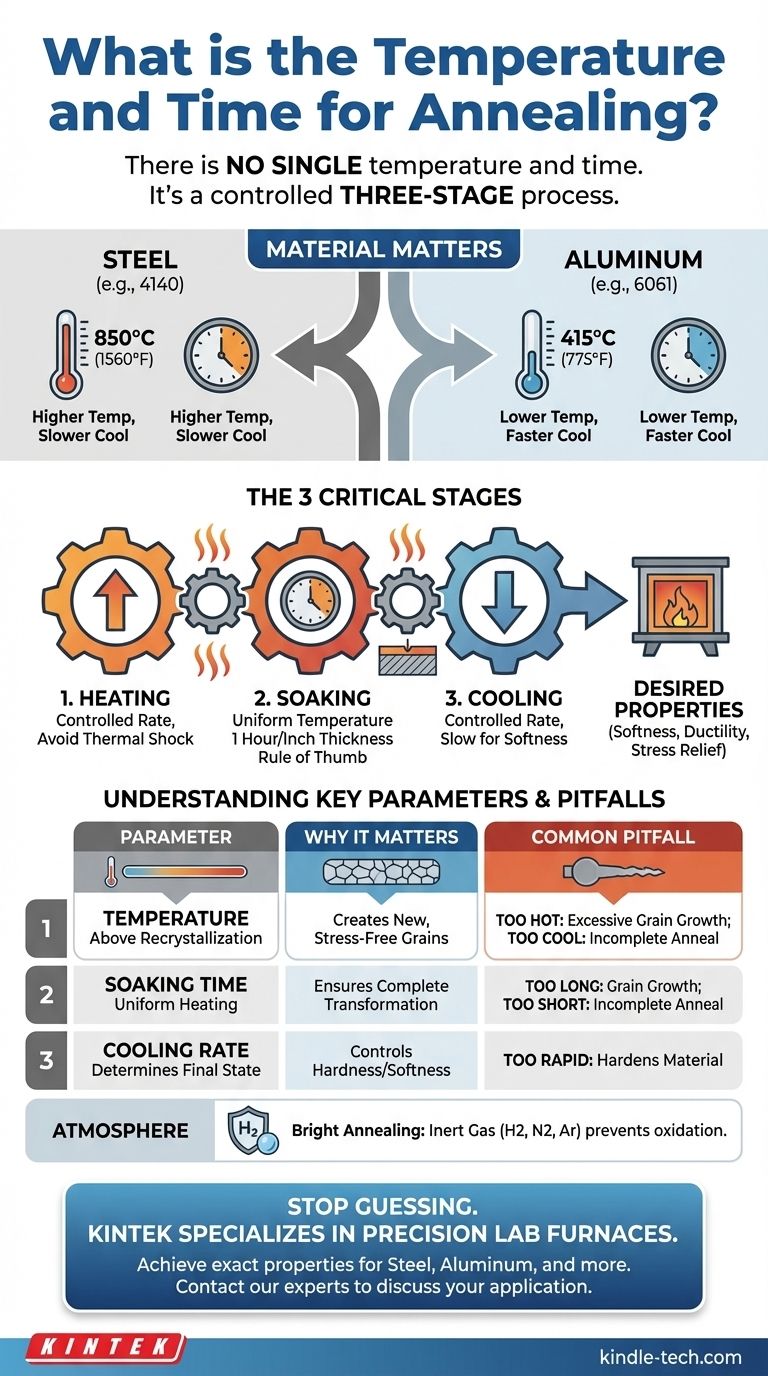

There is no single temperature and time for annealing. These parameters are critically dependent on the specific material being treated, its initial condition, and the desired final properties.

Treating annealing as a universal recipe is the most common point of failure; for example, the correct annealing temperature for a common steel alloy is high enough to melt aluminum.

The core principle of annealing is not about hitting a magic number, but about controlling a three-stage thermal process—heating, soaking, and cooling—each tailored precisely to the material's unique metallurgy and your specific goal.

Why a Universal Answer Doesn't Exist

The goal of annealing is to alter a material's microstructure to achieve a desired outcome. Since every material has a unique structure and responds differently to heat, the process must be customized.

The Role of Material Composition

Different metals and their alloys have vastly different recrystallization temperatures—the point at which new, strain-free grains are formed.

An alloy steel like 4140 requires a temperature around 850°C (1560°F), whereas an aluminum alloy like 6061 anneals at a much lower 415°C (775°F). Using the wrong temperature will either do nothing or damage the material.

The Desired Mechanical Properties

Annealing isn't a single process but a category of treatments. A full anneal aims for maximum softness and ductility, while a stress-relief anneal uses lower temperatures just to remove internal stresses from manufacturing without significantly changing hardness.

The Three Critical Stages of Annealing

Successfully annealing any material requires precise control over three distinct phases. The temperature and time you asked about primarily relate to the second stage, but it's meaningless without the others.

Stage 1: Heating to Temperature

The material is heated at a controlled rate to the target annealing temperature. Heating too quickly can induce thermal shock and stress, especially in complex parts.

Stage 2: Soaking (Temperature and Time)

This is the phase where the material is held at the target temperature. The goal is to allow the entire part, from surface to core, to reach a uniform temperature and for the necessary microstructural changes to occur.

Soaking time is often determined by the thickest cross-section of the part—a common rule of thumb is one hour per inch of thickness, but this is only a starting point.

Stage 3: Controlled Cooling

The cooling rate is just as critical as the heating temperature. For a full anneal to produce a soft, ductile structure in steel, it must be cooled extremely slowly, often by leaving it inside the furnace as it cools. Quenching or rapid cooling will produce a hard structure, defeating the purpose.

Understanding the Key Parameters and Trade-offs

Choosing the right parameters involves balancing desired outcomes with potential pitfalls.

Finding the Right Temperature

The most important parameter is the recrystallization temperature. For most processes, the annealing temperature is set slightly above this point.

This temperature ensures that the distorted, high-energy grains created during cold working are replaced by new, stress-free grains, which restores ductility and reduces hardness.

The Risk of Too Hot or Too Long

Exceeding the optimal temperature or holding it for too long can lead to excessive grain growth. While the material will be soft, large grains can degrade toughness and result in poor surface finish after forming.

The Risk of Too Cool or Too Short

Failing to reach the required temperature or not soaking for long enough will result in an incomplete anneal. The microstructure will not fully transform, and the material will not achieve the desired level of softness or stress relief.

The Importance of Atmosphere

For a clean, oxide-free surface, a process called bright annealing is used. This is performed in a controlled, inert atmosphere.

As your reference material notes, common atmospheres include pure hydrogen, nitrogen, or argon. This protective atmosphere prevents oxidation, which would otherwise form a layer of scale on the material's surface at high temperatures.

How to Determine the Right Parameters for Your Project

To find the correct starting point, you must consult a material data sheet or a metallurgical handbook for the specific alloy you are working with.

- If your primary focus is maximum softness and ductility: You are likely performing a full anneal, which requires heating above the material's upper transformation temperature and then cooling very slowly in the furnace.

- If your primary focus is removing internal stress from welding or machining: You need a stress-relief anneal, which uses a lower temperature (below the transformation point) and is primarily concerned with uniform soaking and slow cooling.

- If your primary focus is improving machinability in high-carbon steel: You may require a specific cycle called spheroidize annealing, which involves prolonged holding just below the lower transformation temperature to create a specific microstructure.

Ultimately, the right parameters are found by consulting reliable technical data for your specific material and confirming them with testing.

Summary Table:

| Parameter | Why It Matters | Common Pitfall |

|---|---|---|

| Temperature | Must be above the material's recrystallization point to soften it. | Wrong temperature can damage the material or do nothing. |

| Soaking Time | Ensures the entire part heats uniformly for microstructural changes. | Too short: incomplete anneal. Too long: excessive grain growth. |

| Cooling Rate | Determines the final material properties (e.g., softness vs. hardness). | Rapid cooling can harden the material, defeating the purpose. |

Stop guessing your annealing parameters.

KINTEK specializes in precision lab furnaces and consumables, providing the controlled heating environments necessary for successful annealing processes—whether you're working with steel, aluminum, or other alloys.

Our experts can help you select the right equipment to achieve the exact material properties you need, from full softness to stress relief.

Contact our thermal processing experts today to discuss your specific material and application.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing