At its core, heat treatment is a controlled process of heating and cooling metals to deliberately alter their physical and mechanical properties. The primary properties affected are a material's hardness, strength, toughness, ductility, and wear resistance. These changes are achieved without altering the fundamental shape of the component.

The central purpose of heat treatment is to manipulate a material's internal crystalline structure, or microstructure. By controlling this internal architecture, we can precisely tune the final mechanical properties to meet the demands of a specific application.

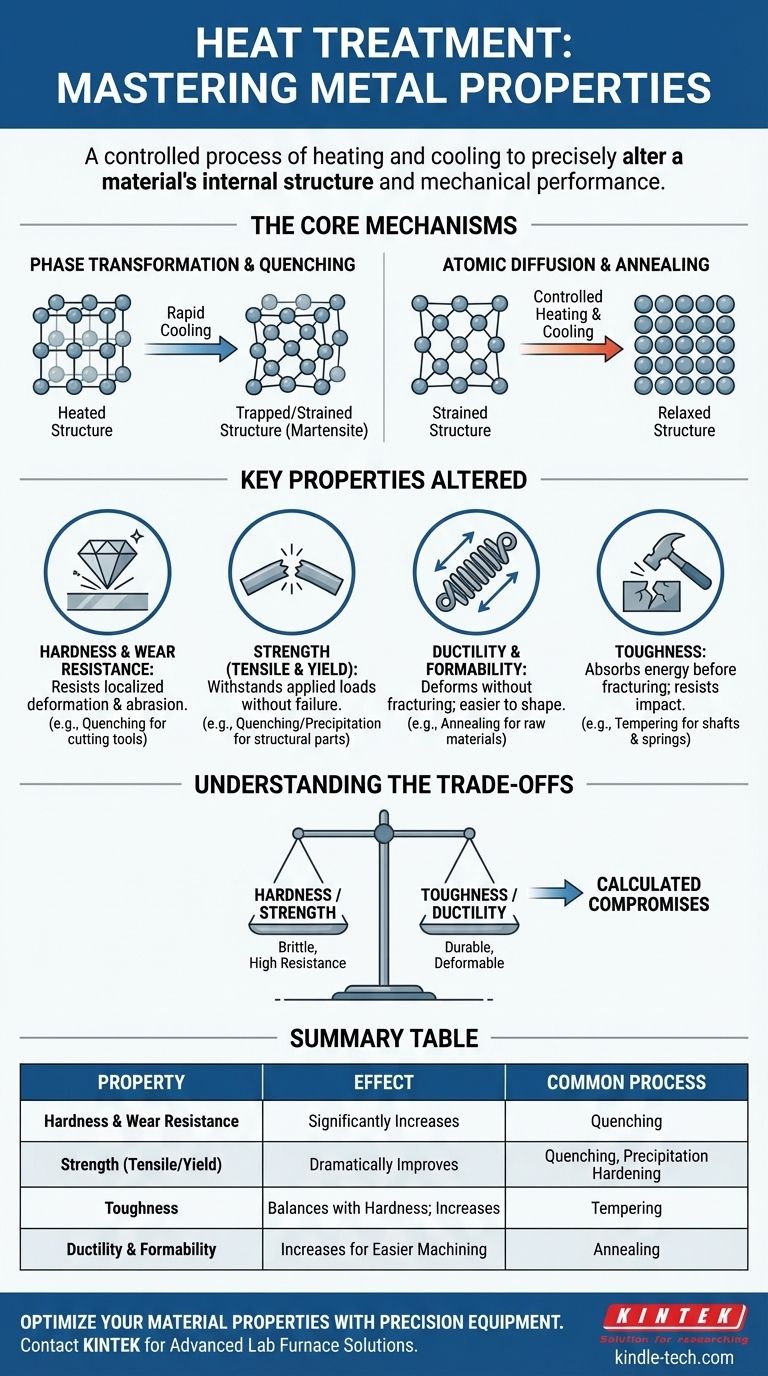

The Core Mechanisms: How Heat Treatment Works

To understand which properties change, you must first understand the two fundamental mechanisms at play inside the metal. These processes rearrange the atoms and crystal structures, which in turn dictates the material's behavior.

Phase Transformation and Crystal Deformation

At high temperatures, the atoms in many alloys (like steel) arrange themselves into a specific crystal structure. If the metal is cooled very rapidly, or quenched, the atoms don't have time to rearrange into their normal, relaxed state.

This process traps them in a highly strained and distorted structure, such as martensite. This internal deformation of the crystal lattice is the primary source of the extreme hardness gained through certain heat treatments.

Atomic Diffusion and Homogenization

In contrast to quenching, slower heating and cooling cycles allow time for atoms to move around within the crystal structure—a process called diffusion.

This controlled atomic movement can relieve internal stresses, create a more uniform and homogenous chemical composition throughout the alloy, and allow for the formation of tiny, strengthening particles in a process called precipitation hardening.

Key Properties Altered by Heat Treatment

The microscopic changes from transformation and diffusion have a direct impact on the macroscopic properties we observe and rely on in engineering.

Hardness and Wear Resistance

Hardness is a material's ability to resist localized deformation, such as scratching or indentation. By forming a hard microstructure like martensite, quenching can dramatically increase a material's hardness and its resistance to wear.

Strength (Tensile and Yield)

Strength refers to a material's ability to withstand an applied load without deforming or breaking. Both the rapid quenching that forms martensite and the slower, controlled precipitation of strengthening particles significantly increase a material's tensile and yield strength.

Ductility and Formability

Ductility is a measure of how much a material can deform under tensile stress before it fractures, a key factor in its ability to be formed into shapes. Processes like annealing, which rely on diffusion, soften the material, relieve internal stresses, and make it more ductile and easier to machine or bend.

Toughness

Toughness is a material's ability to absorb energy and deform plastically before fracturing. It is distinct from hardness. While a fully hardened material is strong, it is often brittle (low toughness). A subsequent treatment like tempering uses diffusion to slightly reduce hardness while dramatically increasing toughness.

Understanding the Trade-offs

Heat treatment is not a magic bullet; it is a series of calculated compromises. Changing one property almost always affects another, and understanding these relationships is critical.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off in heat treatment. A material that is quenched to its maximum hardness is typically very brittle and susceptible to cracking under impact. Tempering is the essential follow-up step that sacrifices some hardness to gain crucial toughness, making the part more durable and reliable.

Strength vs. Ductility

Similarly, processes that significantly increase a material's strength often reduce its ductility. The material becomes more resistant to deformation, but it will also break with less warning or "give." The chosen treatment must align with whether the part needs to bear a heavy load or be able to bend without failing.

Risk of Distortion and Cracking

The rapid temperature changes involved in heat treatment, especially quenching, introduce immense internal stresses. If not managed carefully, these stresses can cause the part to warp, distort, or even crack during or after the process.

Matching the Treatment to the Goal

The right heat treatment is entirely dependent on the final application of the component.

- If your primary focus is maximum hardness and wear resistance (e.g., for cutting tools or bearings): Quenching is the key process, often followed by a very low-temperature temper.

- If your primary focus is toughness and impact resistance (e.g., for structural components, shafts, or springs): The standard approach is quenching followed by tempering at a higher temperature to achieve a durable balance of properties.

- If your primary focus is machinability and formability (e.g., for raw material before manufacturing): Annealing is used to put the material in its softest, least-stressed state.

- If your primary focus is high strength in a non-ferrous alloy (e.g., for aluminum aircraft components): Age or precipitation hardening is the appropriate method.

Ultimately, heat treatment gives us the power to transform a standard material into a high-performance component tailored for its specific task.

Summary Table:

| Property | Effect of Heat Treatment | Common Treatment Process |

|---|---|---|

| Hardness & Wear Resistance | Significantly increases | Quenching |

| Strength (Tensile/Yield) | Dramatically improves | Quenching, Precipitation Hardening |

| Toughness | Balances with hardness; increases | Tempering |

| Ductility & Formability | Increases for easier machining | Annealing |

Need to Optimize Your Material Properties?

Heat treatment is a precise science. Whether your application requires maximum hardness for cutting tools, superior toughness for structural components, or improved machinability, the right equipment is critical to achieving consistent, high-quality results.

KINTEK specializes in advanced lab furnaces and heat treatment equipment designed for reliability and precision. Our solutions help you accurately control the heating and cooling cycles that define your material's final properties.

Let us help you tailor your materials for peak performance. Contact our experts today to discuss your specific laboratory needs and discover the right heat treatment solution for you.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- Why is ceramic used in making furnace? Achieve Superior Heat Resistance and Efficiency

- What is the difference between a muffle furnace and an electric furnace? A Guide to Precision Heating

- What is a muffle furnace in the food industry? A Key Tool for Accurate Nutritional Analysis

- What is the maintenance of laboratory equipment? Ensure Data Integrity and Extend Equipment Lifespan

- What is the difference between muffle furnace and hot oven? A Guide to Choosing the Right Thermal Tool