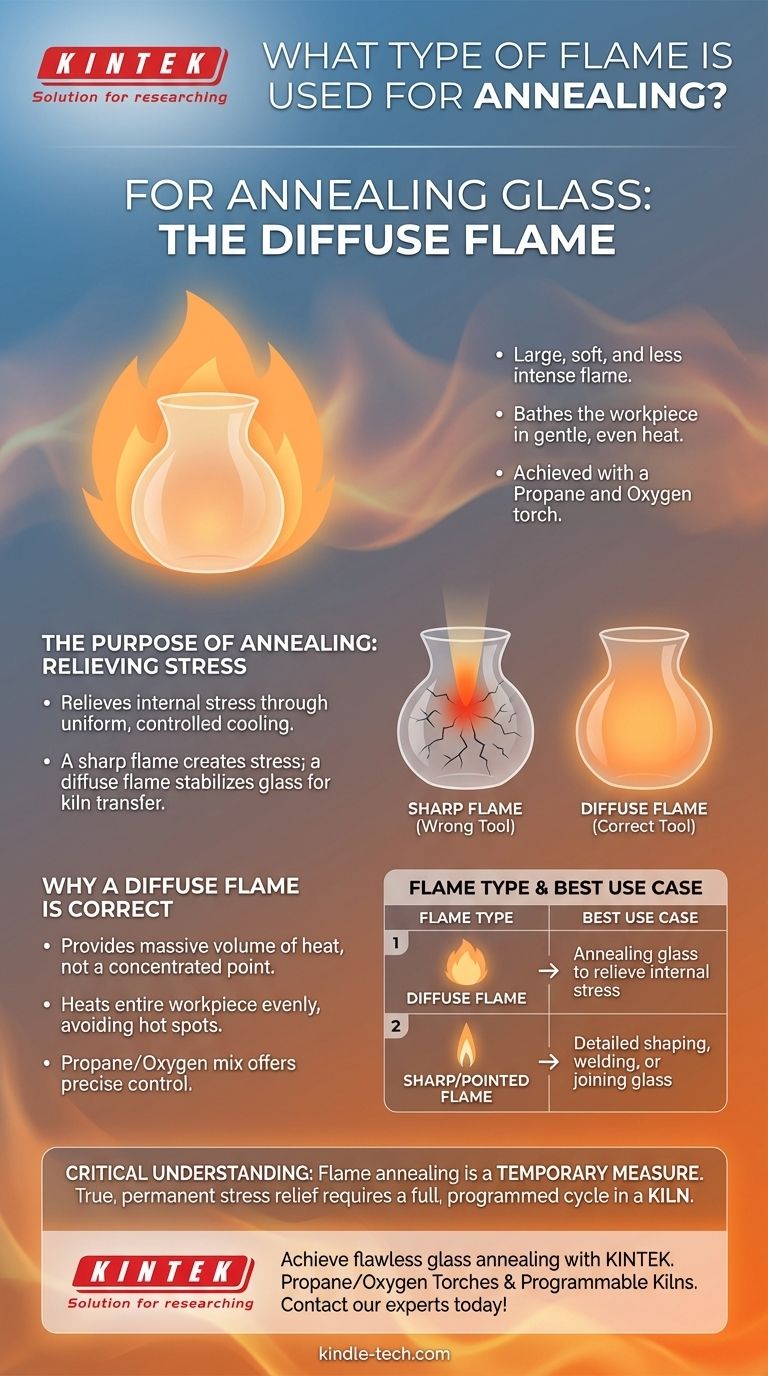

For annealing glass, the correct tool is a diffuse flame. This is a large, soft, and less intense flame that bathes the workpiece in gentle, even heat. For anything beyond very small pieces, this is achieved with a propane and oxygen torch, not a simple propane-only torch.

The core principle of annealing is to relieve internal stress through uniform, controlled cooling. A sharp, concentrated flame creates stress, while a large, diffuse flame provides the broad, gentle heat needed to stabilize the glass before it can be properly cooled in a kiln.

The Purpose of Annealing: Relieving Stress

What is Annealing?

Annealing is a critical process in glassworking that involves heating a finished piece to a uniform temperature and then cooling it down very slowly according to a specific schedule.

This controlled cooling process removes internal stresses that develop as different parts of the glass cool at different rates during its creation.

Why Stress is the Enemy

As glass cools from a molten state, the surface cools faster than the interior. This differential creates immense internal tension.

Glass with high internal stress is extremely fragile. It can crack or shatter spontaneously, days or even weeks after it was made, often due to a minor temperature change or vibration.

The Goal: Uniform Temperature

The goal of flame annealing is not to reshape the glass, but to gently soak the entire piece in heat. This brings the entire object to a consistent temperature, relaxing the internal stress before it undergoes a full, controlled cooling cycle in a kiln.

Why a Diffuse Flame is the Correct Tool

Defining the Diffuse Flame

A diffuse flame is the opposite of a sharp, pinpoint flame used for detailed shaping or welding. It is often described as bushy, soft, or "lazy."

It's a large, lower-velocity flame that provides a massive volume of heat rather than a concentrated, high-temperature point.

The Benefit of Broad, Gentle Heat

This large flame allows you to heat the entire workpiece evenly without creating new hot spots. It essentially "bathes" the glass in warmth.

Using a sharp flame would introduce new temperature differences and add more stress, defeating the entire purpose of the annealing process.

The Role of a Propane/Oxygen Mix

While a propane-only torch can create a flame, it often lacks the heat volume (BTUs) and control needed for effective annealing, especially on borosilicate glass which has a higher working temperature.

A propane/oxygen system gives the artist precise control over the flame chemistry and size, allowing them to create the large, diffuse, and sufficiently hot flame required for the job.

Understanding the Pitfalls

The Wrong Tool: A Sharp Flame

Using a sharp, concentrated, or highly oxidizing flame for annealing is a common mistake. This will overheat one spot while leaving others cool, creating more stress and potentially cracking the piece on the spot.

The Limits of Flame Annealing

It is critical to understand that flame annealing is almost always a temporary measure. It is used to keep a piece stable and intact while moving it from the torch to a kiln.

A torch cannot provide the hours-long, digitally controlled, slow-cooling environment that a kiln can. True, permanent stress relief is only achieved through a proper kiln annealing cycle.

Making the Right Choice for Your Goal

To select the right process, you must be clear about your material and your objective.

- If your primary focus is keeping a small bead stable for transfer to a kiln: A propane-only torch might be sufficient, but a propane/oxygen system provides superior control.

- If your primary focus is working with borosilicate or any larger glass object: A propane/oxygen torch is non-negotiable for generating the necessary diffuse flame and heat volume.

- If your primary focus is a permanent, stress-free final product: Flame annealing is only the first step; the workpiece must undergo a full, programmed cycle in a kiln.

Using the correct diffuse flame ensures your work survives the critical transition from creation to permanence.

Summary Table:

| Flame Type | Characteristics | Best Use Case |

|---|---|---|

| Diffuse Flame | Large, soft, low-velocity, gentle heat | Annealing glass to relieve internal stress |

| Sharp/Pointed Flame | Concentrated, high-temperature, intense | Detailed shaping, welding, or joining glass |

Achieve flawless glass annealing with the right equipment from KINTEK.

Mastering the annealing process requires precise control and the right tools. KINTEK specializes in high-quality lab equipment, including torches and kilns designed for professional glassworking. Whether you're a hobbyist or a production studio, our solutions help you achieve consistent, stress-free results.

We provide:

- Propane/Oxygen Torches: For generating the large, diffuse flame necessary for effective annealing.

- Programmable Kilns: For the final, permanent stress-relief cycle that a torch cannot provide.

Let us help you protect your creations from spontaneous cracking. Contact our experts today to find the perfect annealing setup for your needs!

Visual Guide

Related Products

- Mesh belt controlled atmosphere furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- Why Use Ultra-High Vacuum Furnaces for LLZO? Ensure Chemical Stability & Interface Integrity in Solid Electrolytes

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification

- Why is a high-precision atmosphere furnace essential for high-nickel cathode sintering? Unlock Battery Performance

- What advantages does a high-temperature atmosphere sintering furnace offer for UO2? Precision Fuel Densification

- Why is a horizontal tube furnace with a H2-N2 atmosphere used for NiO pre-treatment? Key to Catalyst Activation