In short, metal almost universally expands when heated and contracts when cooled. This fundamental behavior, known as thermal expansion, is a direct result of how atoms react to changes in energy. When heat is applied, the atoms within the metal absorb energy, causing them to vibrate more vigorously and push against each other, which increases the metal's overall volume.

The core principle is simple: heat is energy. Adding energy to a metal's atoms makes them move more, forcing them to take up more space. Removing that energy allows them to settle closer together, causing the object to shrink.

The Physics of Thermal Expansion

To truly understand why metals behave this way, we need to look at what's happening at the atomic level. The solid, static object we see is actually a hive of constant, microscopic motion.

The Role of Kinetic Energy

Heat is a form of energy. When you introduce heat to a piece of metal, you are transferring kinetic energy to its atoms.

This added energy doesn't make the atoms move from their fixed positions in the metal's crystalline structure, but it does make them vibrate much more rapidly and intensely.

Atomic Vibration and Spacing

Imagine the atoms in a metal are connected to each other by springs. As they gain kinetic energy from heat, they start to "dance" or vibrate more aggressively.

This increased vibration forces each atom to push its neighbors further away, increasing the average distance between them. When this happens across trillions of atoms, the entire object expands in size.

Contraction: The Opposite Effect

Cooling is simply the process of removing heat energy. As the metal cools, its atoms lose kinetic energy.

Their vibrations slow down, and the forces holding them together can pull them into a more compact arrangement. This decrease in the average distance between atoms results in the overall contraction, or shrinking, of the metal.

Why This Matters in the Real World

This principle isn't just a textbook concept; it has massive, tangible effects on engineering, construction, and even everyday objects. Ignoring thermal expansion can lead to catastrophic failure.

Engineering and Construction

The most classic example is an expansion joint in a bridge or a highway overpass. These small, gapped segments allow the structure to safely expand in the summer heat and contract in the winter cold without buckling or cracking.

Similarly, railway tracks are often laid with small gaps between the rails to accommodate expansion and prevent the tracks from warping on a hot day, which could derail a train.

Bimetallic Strips in Thermostats

Different materials expand at different rates, a property measured by the coefficient of thermal expansion. A bimetallic strip is made by bonding two different metals (like steel and copper) together.

When heated, the copper expands more than the steel, causing the strip to bend. This bending action can be used as a switch to turn a heating or cooling system on or off, which is the mechanism behind many older thermostats.

Everyday Examples

A common household example is a tight metal lid on a glass jar. Running hot water over the lid causes it to expand more than the glass, making it easier to twist off. The metal expands just enough to loosen its grip.

Understanding the Nuances

While the core rule is straightforward, a few details provide a more complete picture of the phenomenon.

It's Not Just About Length

When an object heats up, it doesn't just get longer. It expands in all three dimensions—length, width, and height. This is known as volumetric expansion.

For objects like a long, thin wire, the change in length is the most noticeable, but the expansion is happening uniformly.

A Nearly Universal Rule for Metals

For solid metals under normal conditions, the rule that they expand on heating and contract on cooling is essentially universal.

While some non-metallic substances (most famously, water between 0°C and 4°C) exhibit anomalous expansion where they expand upon cooling, this behavior is not observed in metals.

Applying This to Your Goal

Understanding this principle is critical for anyone working with physical materials, whether in engineering, fabrication, or simple repairs.

- If your primary focus is engineering or construction: You must always design with thermal expansion in mind to prevent structural stress and failure, incorporating features like expansion joints.

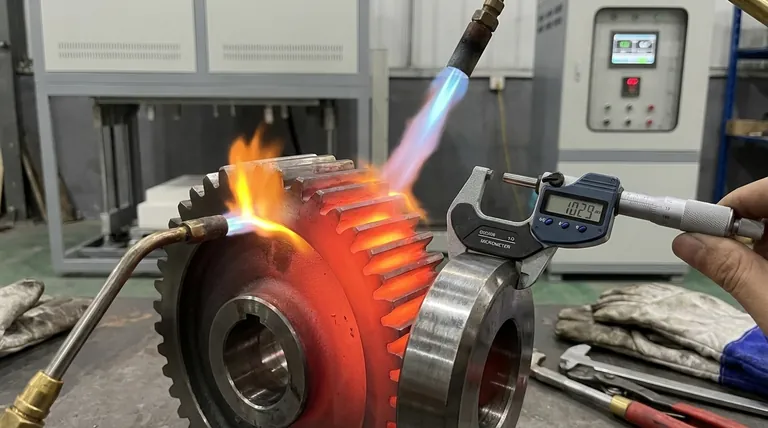

- If your primary focus is precision machining: You must control for temperature variations during fabrication, as even small changes can affect tolerances and the final dimensions of a part.

- If you are simply curious about the physical world: Remember that the invisible motion of atoms has powerful and visible consequences on the largest and smallest objects we build.

By grasping this fundamental principle, you can anticipate how materials will behave and better predict the forces shaping our engineered world.

Summary Table:

| Behavior | Cause | Effect |

|---|---|---|

| Expansion on Heating | Atoms gain kinetic energy and vibrate more, increasing the average distance between them. | The metal's volume increases in all dimensions (length, width, height). |

| Contraction on Cooling | Atoms lose kinetic energy, vibrations slow down, and atomic forces pull atoms closer. | The metal's volume decreases, causing it to shrink. |

Need precise control over material behavior in your lab?

Understanding thermal expansion is just the first step. Applying this knowledge to your specific processes requires reliable equipment. Whether you're conducting heat treatment, sintering, or any process involving temperature changes, KINTEK's range of high-precision lab furnaces and ovens ensures consistent, uniform heating and cooling for accurate, repeatable results.

Let KINTEK, your partner in laboratory excellence, provide the durable, high-performance equipment your research demands.

Contact our experts today to discuss how our solutions can enhance your workflow and precision.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between catalytic pyrolysis and pyrolysis? Unlock Higher-Quality Biofuels

- What is a rotavap used for? Achieve Fast, Gentle Solvent Evaporation for Your Lab

- Why inert gas is used in sputtering? Ensure Pure, Contamination-Free Thin Film Deposition

- How does a high-power ultrasonic homogenizer assist in the preparation of organic-inorganic nanocomposites?

- What are the characteristics of lab grown diamonds? A Guide to Their Identity, Value, and Ethics

- How effective is electric heating? Uncover the Truth About Efficiency and Cost

- Why is the industrial process of titanium so expensive? The High Cost of Taming a Reactive Metal

- What is the process of sintering reaction? Transform Powder into Dense, High-Performance Parts