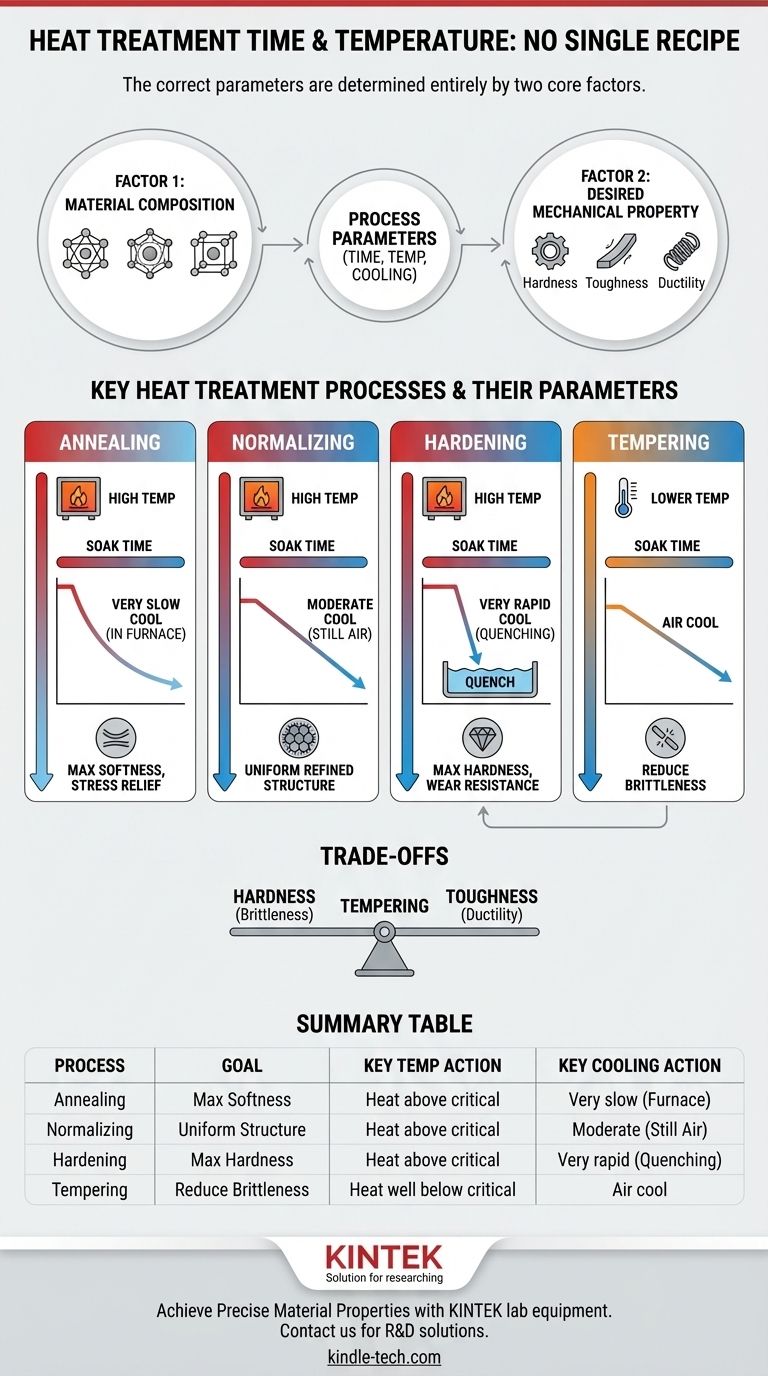

There is no single time and temperature for heat treatment. The correct parameters are determined entirely by two factors: the specific material being treated and the desired final properties. For example, the process to make steel softer for machining is fundamentally different from the process to make it extremely hard and wear-resistant.

Heat treatment is not a single recipe but a family of controlled thermal processes. The specific time, temperature, and cooling rate are precisely chosen to manipulate the material's internal microstructure, thereby achieving a targeted set of mechanical properties like hardness, toughness, or ductility.

The Core Factors: Material and Desired Outcome

To determine the correct heat treatment parameters, you must first define your material and your goal. These two variables dictate every subsequent step of the process.

Factor 1: The Material Composition

The chemical makeup of a metal alloy dictates its critical transformation temperatures. For steel, the carbon content is the most significant element influencing how it responds to heat.

A high-carbon tool steel will have different critical temperatures and require a different process than a low-carbon structural steel. Always consult the material's specific datasheet for its transformation diagrams (like TTT or CCT curves) which guide these decisions.

Factor 2: The Desired Mechanical Property

The "why" behind your heat treatment is the most important question. As the references note, the goals can vary widely, and each goal corresponds to a different process.

Are you trying to relieve internal stresses from welding, increase surface hardness for wear resistance, or improve ductility for a forming operation? Each of these outcomes requires a unique thermal cycle.

Key Heat Treatment Processes and Their Parameters

Below are the most common heat treatment processes for steel, illustrating how time and temperature are adjusted to achieve different results.

Annealing: For Maximum Softness and Stress Relief

Annealing is used to make a material as soft and ductile as possible, often to improve its machinability.

The process involves heating the steel to just above its upper critical temperature, holding it there long enough for the entire part to reach that temperature (called "soaking"), and then cooling it very slowly, often by leaving it inside the furnace as it cools.

Normalizing: For a Uniform, Refined Structure

Normalizing is often performed after hot-working processes like forging to create a more uniform and refined grain structure.

This involves heating the steel to a temperature similar to annealing, but the part is then cooled in still air. This faster cooling rate produces a slightly harder and stronger material than an annealed part.

Hardening: For Maximum Strength and Wear Resistance

Hardening is used to make steel significantly harder and more brittle.

The steel is heated above its critical temperature and then cooled very rapidly in a process called quenching. The quenching medium (water, brine, oil, or even air) is chosen based on the steel type and the cooling speed required to achieve full hardness.

Tempering: For Reducing Brittleness

A hardened part is often too brittle for practical use. Tempering is a secondary process performed after hardening to regain some toughness.

The hardened part is reheated to a much lower temperature, well below its critical point, and held for a specific time. The exact tempering temperature determines the final balance of hardness and toughness; a higher temperature results in a softer but tougher part.

Understanding the Trade-offs

Heat treatment is a game of compromise. Improving one property, like hardness, often comes at the expense of another, like toughness.

The Hardness vs. Brittleness Compromise

The primary trade-off in treating steel is between hardness and toughness. The quenching process that creates extreme hardness also creates extreme brittleness.

Tempering is the essential step used to negotiate this compromise, sacrificing some hardness to gain the necessary toughness and prevent the part from shattering in service.

The Impact of Part Size and Geometry

A thick, heavy part requires a longer "soak time" at the target temperature to ensure the core becomes fully heated. Insufficient soaking will result in an uneven heat treatment.

Furthermore, rapid quenching can cause thin or complex parts to warp, distort, or even crack due to uneven thermal stresses.

Making the Right Choice for Your Goal

Always start with your desired outcome. The goal dictates the process, which in turn dictates the time, temperature, and cooling rate.

- If your primary focus is machinability and stress relief: Annealing is your process, defined by a very slow cool-down from a high temperature.

- If your primary focus is maximum hardness and wear resistance: Hardening (quenching) followed by tempering is the required two-step sequence.

- If your primary focus is refining the grain structure after forming: Normalizing is a cost-effective choice that uses air cooling to balance strength and ductility.

- If your primary focus is reducing brittleness in a hardened part: Tempering is a mandatory post-hardening step, where the temperature is precisely chosen to achieve the ideal toughness.

Ultimately, selecting the correct time and temperature requires you to first understand the metallurgical change you intend to create.

Summary Table:

| Process | Goal | Key Temperature Action | Key Cooling Action |

|---|---|---|---|

| Annealing | Maximum softness, stress relief | Heat above critical temperature | Very slow (in furnace) |

| Normalizing | Uniform, refined grain structure | Heat above critical temperature | Moderate (in still air) |

| Hardening | Maximum hardness, wear resistance | Heat above critical temperature | Very rapid (quenching) |

| Tempering | Reduce brittleness after hardening | Heat well below critical temperature | Air cool |

Achieve Precise Material Properties with KINTEK

Navigating the complexities of heat treatment parameters is critical to your product's performance. Whether your goal is maximum hardness, improved ductility, or stress relief, the right laboratory equipment is essential for developing and validating your thermal processes.

KINTEK specializes in high-quality lab furnaces, ovens, and consumables that provide the precise temperature control and uniform heating your heat treatment R&D demands. Our equipment helps metallurgists, materials scientists, and manufacturing engineers accurately replicate industrial processes on a lab scale, ensuring your final product meets exact specifications.

Let us help you optimize your heat treatment cycles.

Contact our experts today to discuss your specific application and find the perfect laboratory solution for your needs.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a calcining furnace? Transform Materials with Controlled High-Temperature Processing

- What is the annealing process on properties? Achieve Softer, More Ductile Materials

- Why is a vacuum oven used for 120°C degassing of carbon aerogels? Ensure Purity and Structural Integrity

- What is the function of high-temperature furnaces in HPQ processing? Optimize Quartz Calcination & Quenching

- What is the capacity of a furnace? From Home Heating to Industrial Processes

- How does sintering temperature affect hardness? Optimize for Maximum Material Strength

- What is the critical role of a vacuum furnace in the calcination of TiO2? Optimize Your Powder Microstructure

- What is brazing mainly used for? Precision Joining for Aerospace, Electronics & More