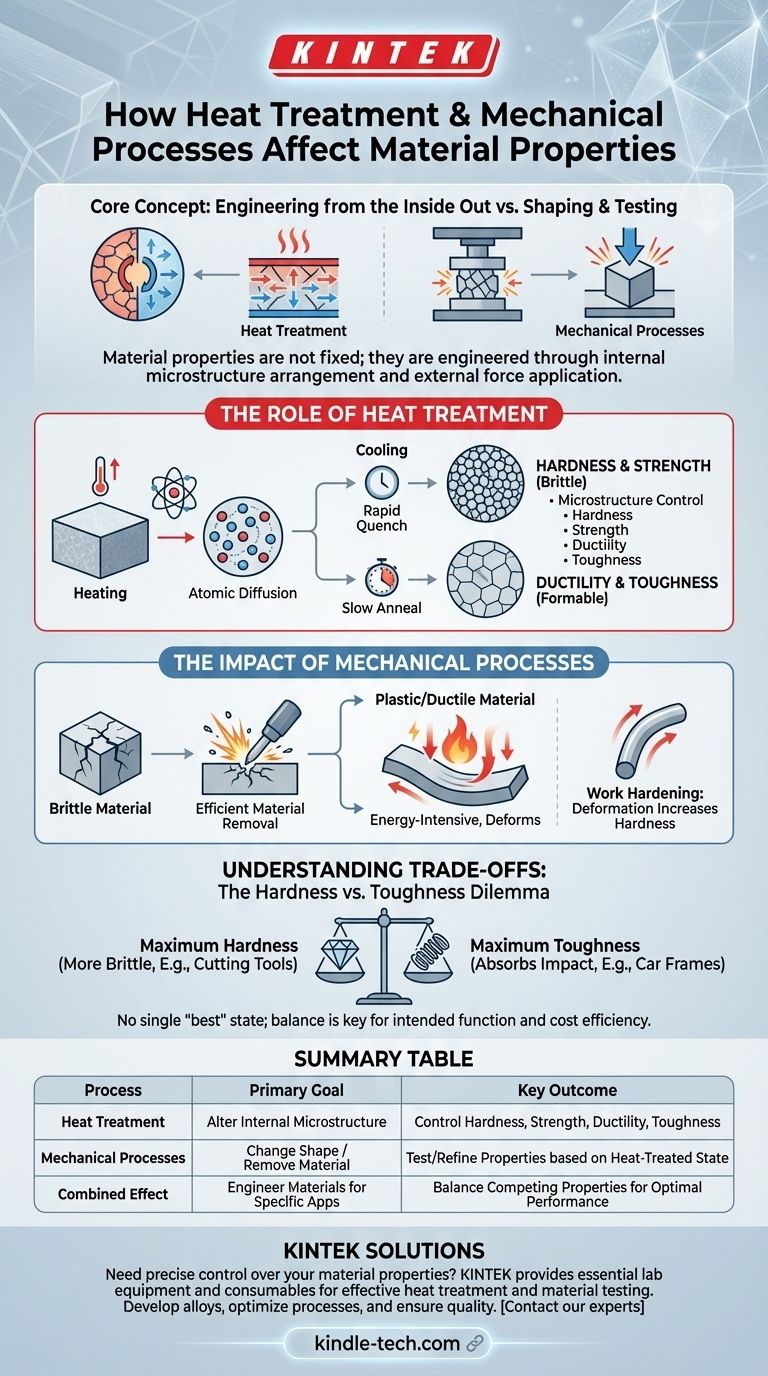

At their core, heat treatment and mechanical processes are the primary methods for controlling a material's final properties. Heat treatment alters a material's internal atomic structure to change characteristics like hardness and strength, while mechanical processes test or reshape the material based on those intrinsic properties. These methods work in tandem to transform a raw alloy into a component engineered for a specific purpose.

The fundamental takeaway is that material properties are not fixed. Heat treatment engineers the material from the inside out by arranging its microstructure, while mechanical processes reveal, test, or further refine those properties through external force.

The Role of Heat Treatment: Engineering from the Inside Out

Heat treatment is a deliberate and controlled process of heating and cooling a material, most often a metallic alloy, to achieve specific, desirable properties. It does not change the shape of the part, only its internal state.

The Goal: Controlling the Microstructure

The properties of a metal are determined by its microstructure—the specific arrangement of its crystalline grains and phases at a microscopic level. Heat treatment is the tool used to manipulate and control this structure.

Key Levers: Heating and Cooling

By heating a metal, you give its atoms enough energy to move, a process called diffusion. This allows the internal structure to rearrange.

The rate of cooling then "locks in" a particular microstructure. A very rapid cool (quenching) traps a different structure than a very slow cool (annealing), each with unique properties.

The Outcome: Altering Mechanical Properties

This microstructural control directly translates to changes in mechanical properties. You can precisely adjust the balance of:

- Hardness: Resistance to scratching and indentation.

- Strength: Ability to withstand force without deforming or breaking.

- Ductility: Ability to deform without fracturing (e.g., being drawn into a wire).

- Toughness: Ability to absorb energy and resist shattering upon impact.

The Impact of Mechanical Processes: Shaping and Testing

Mechanical processes involve applying force to change a material's shape (e.g., forging, stamping) or to remove material (e.g., machining, grinding). How a material responds is a direct consequence of its heat-treated properties.

Brittle vs. Plastic Behavior

A material's properties dictate how it reacts to force. This is clearly seen in processes like grinding.

A brittle material, which fractures easily, requires relatively little energy to grind. The applied energy efficiently creates new fractures.

A plastic or ductile material deforms extensively before it breaks. In grinding, this means much of the energy is wasted deforming particles rather than fracturing them, making the process 10 to 100 times more energy-intensive.

Work Hardening: A Consequence of Deformation

The act of mechanically deforming a metal can itself alter its properties. Bending, rolling, or forging a metal at a low temperature can increase its hardness and strength, a phenomenon known as work hardening.

Understanding the Trade-offs

Choosing a processing path is always an exercise in balancing competing properties. There is no single "best" state for a material; it must be optimized for its intended function.

The Hardness vs. Toughness Dilemma

This is the most common trade-off in materials engineering. Processes that significantly increase a material's hardness almost always decrease its toughness, making it more brittle.

A file needs to be extremely hard to cut other metals, but it will shatter if dropped. A car frame needs to be tough to absorb impact energy in a crash, so it is designed to bend and deform rather than shatter.

Efficiency and Cost

The properties of a material directly impact manufacturing costs. As noted, grinding a highly plastic material requires immense energy, increasing operational expenses.

Sometimes, a material is intentionally heat-treated to a more brittle state simply to make it easier and cheaper to machine, before being re-treated to achieve its final desired properties.

How to Apply This to Your Goal

Your choice of heat treatment and mechanical processing depends entirely on the component's end-use.

- If your primary focus is maximum hardness and wear resistance: You will need a heat treatment involving rapid cooling (quenching), but must account for the resulting decrease in toughness.

- If your primary focus is toughness and formability: You should use a process like annealing (slow cooling) to create a softer, more ductile microstructure that can withstand deformation.

- If your primary focus is efficient material removal: The ideal prior heat treatment is one that makes the material brittle enough to machine or grind easily, minimizing energy consumption and tool wear.

Mastering the interplay between heat, force, and atomic structure is the essence of modern materials engineering.

Summary Table:

| Process | Primary Goal | Key Outcome |

|---|---|---|

| Heat Treatment | Alter internal microstructure | Control hardness, strength, ductility, toughness |

| Mechanical Processes | Change shape or remove material | Test or refine properties based on heat-treated state |

| Combined Effect | Engineer materials for specific applications | Balance competing properties for optimal performance |

Need precise control over your material properties? KINTEK specializes in the lab equipment and consumables essential for effective heat treatment and material testing. Whether you're developing alloys, optimizing manufacturing processes, or ensuring quality control, our solutions help you achieve the perfect balance of hardness, strength, and toughness. Contact our experts today to discuss how we can support your laboratory's specific material engineering needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Why is a high-temperature muffle furnace required for xLi2ZrO3–(1−x)Li4SiO4? Ensure Ceramic Structural Integrity

- How does the temperature control precision of a programmable furnace affect Nb-Ti alloy powders? Master Ductility

- What is the function of a high-temperature ashing furnace? Essential Insights for Carbonized Solid Fuel Analysis

- What is the mechanism of a muffle furnace? Master Precise, Contaminant-Free Heating

- What role does a laboratory box resistance furnace play in optimizing modified SA508 alloys? Enhance RPV Steel Research

- What is the purpose of using high-temperature heating equipment for the 393 K thermal treatment of TiS2/LiBH4? Optimize Interfaces

- What role does a high-temperature muffle furnace play in the strain engineering of functional materials? Precise Control

- What is the temperature range of a laboratory muffle furnace? Find the Right Model for Your Application