The primary way to control the temperature of an induction heating process is by precisely regulating the electrical power delivered to the induction coil. You are not directly setting a temperature on the coil itself; you are controlling the rate of energy transfer to the workpiece. This is achieved by adjusting the magnitude and frequency of the alternating current flowing through the coil, which in turn governs the intensity of the heating effect.

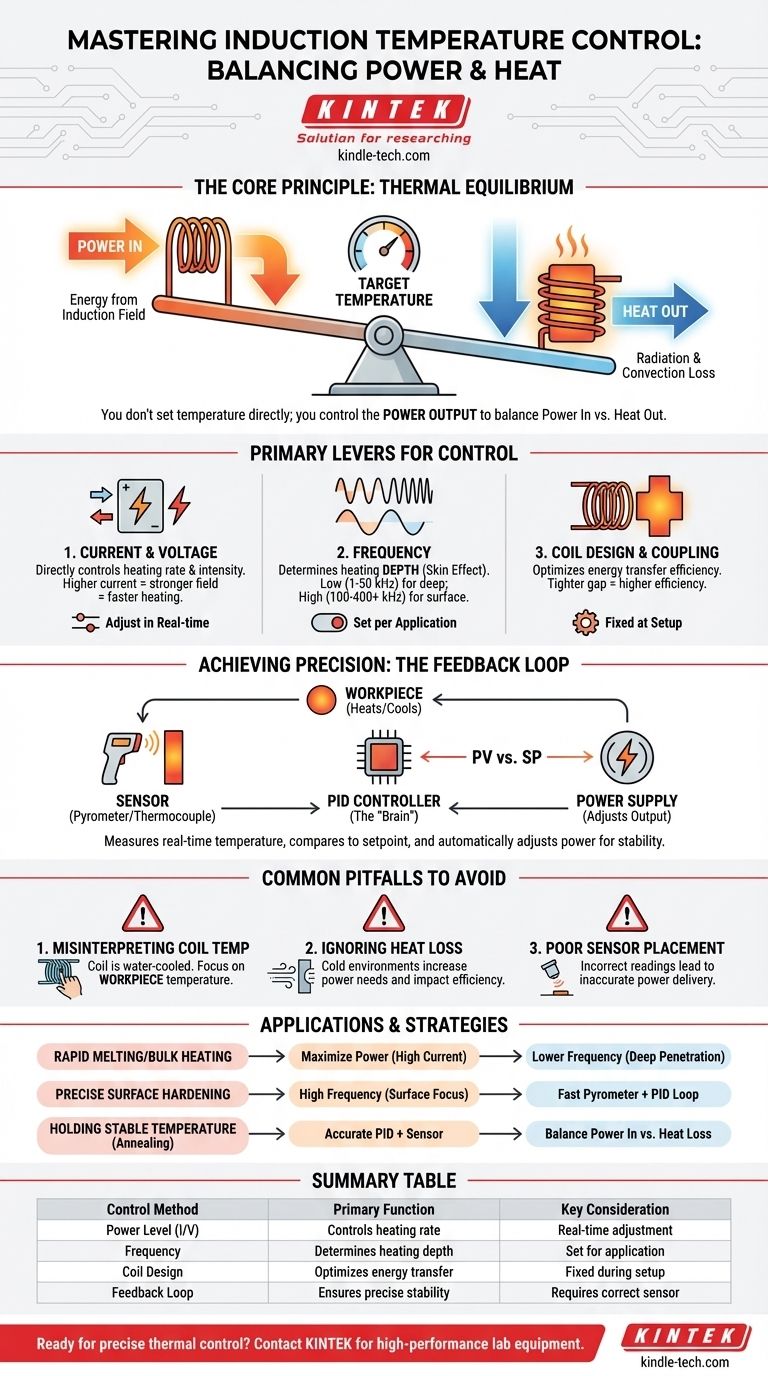

The core principle is that you don't directly control the temperature, you control the power output. Achieving a stable target temperature in the workpiece requires balancing the power you put in via the induction field with the heat the workpiece naturally loses to its surroundings.

The Core Principle: Power In vs. Heat Out

An induction system heats a metal part (the workpiece) placed inside the coil. The final temperature of that part is not a fixed property but the result of a thermal equilibrium.

Understanding Thermal Balance

The induction field constantly adds thermal energy to the workpiece—this is Power In. Simultaneously, the hot workpiece loses energy to the environment through radiation and convection—this is Heat Out.

To raise the temperature, Power In must be greater than Heat Out. To hold a steady temperature (the setpoint), Power In must precisely equal Heat Out.

Primary Levers for Controlling Induction Power

To manage the thermal balance, you have several levers at your disposal, all of which control the Power In side of the equation.

Adjusting Current and Voltage

The most direct and common method is to adjust the amount of current flowing through the coil. A higher current generates a stronger magnetic field, which induces more powerful electrical currents in the workpiece, resulting in faster and more intense heating. Modern solid-state power supplies allow for near-instantaneous and precise control of this power level.

Modifying Frequency

The frequency of the alternating current is a critical parameter, though it's typically set for a specific application rather than adjusted in real-time. Frequency determines the "skin effect," or how deeply the induced currents penetrate the workpiece.

- Low Frequencies (e.g., 1-50 kHz): Penetrate deeper into the material. This is ideal for melting, through-hardening, or heating large billets.

- High Frequencies (e.g., 100-400+ kHz): Concentrate the heating effect on the surface. This is used for applications like surface hardening, brazing, or soldering.

Optimizing Coil Design

Coil design is a foundational control factor set before a process begins. The efficiency of energy transfer depends heavily on the coupling, which is the proximity and geometric relationship between the coil and the workpiece.

A coil with more turns or a tighter gap between the coil and the part will transfer energy far more efficiently, requiring less power from the supply to achieve the same heating rate.

Achieving Precision with a Feedback Loop

Manually adjusting power to hold a temperature is impractical. Professional systems use a closed-loop feedback system to achieve precise and repeatable temperature control automatically.

The Role of Temperature Sensors

You cannot control what you do not measure. A sensor is required to read the real-time temperature of the workpiece. The two most common types are:

- Infrared Pyrometers: A non-contact sensor that measures temperature by reading the thermal radiation emitted by the part. It is fast and ideal for automated processes.

- Thermocouples: A contact-based probe that must physically touch the workpiece. It is highly accurate but can be slower and less practical for moving parts.

The PID Controller

The sensor sends its reading to a PID (Proportional-Integral-Derivative) controller. This is the "brain" of the temperature control system.

The PID controller constantly compares the sensor's reading (the actual temperature) to the desired temperature (the setpoint). It then automatically calculates and adjusts the output of the power supply to minimize the difference, preventing temperature overshoot and holding the setpoint with remarkable stability.

Common Pitfalls to Avoid

Misinterpreting Coil Temperature

The coil itself is almost always water-cooled and remains relatively cool. You are controlling the temperature of the workpiece inside the coil, not the coil itself.

Ignoring Heat Loss

If the workpiece is in a cold or drafty environment, it will lose heat much faster. The system will need to supply significantly more power to maintain the target temperature, impacting energy efficiency.

Poor Sensor Placement

An improperly aimed pyrometer or a poorly seated thermocouple will provide false readings to the controller. This is a common source of error, leading the system to deliver either too much or too little power, resulting in incorrect workpiece temperatures.

How to Apply This to Your Project

Your approach to temperature control should be dictated by the goal of your heating process.

- If your primary focus is rapid melting or bulk heating: Prioritize maximizing power delivery with high current and select a lower frequency for deep energy penetration.

- If your primary focus is precise surface hardening: Use a high frequency to concentrate the heat and rely on a fast-acting pyrometer and PID controller for tight, repeatable control.

- If your primary focus is holding a stable temperature for annealing or tempering: A highly accurate, closed-loop feedback system with a well-tuned PID controller is essential to perfectly balance power input against consistent heat loss.

Ultimately, mastering induction temperature control comes from understanding that you are managing a dynamic energy balance within your specific material and environment.

Summary Table:

| Control Method | Primary Function | Key Consideration |

|---|---|---|

| Power Level (Current/Voltage) | Directly controls heating rate and intensity | Most common real-time adjustment |

| Frequency | Determines heating depth (skin effect) | Set for application (surface vs. deep heating) |

| Coil Design & Coupling | Optimizes energy transfer efficiency | Fixed per application, crucial for setup |

| Feedback Loop (Sensor + PID) | Provides precise, automatic temperature stability | Requires correct sensor placement and tuning |

Ready to achieve precise thermal control in your lab? KINTEK specializes in high-performance lab equipment, including induction heating systems tailored for your specific materials and processes. Our experts can help you select the right system and optimize it for maximum efficiency and repeatability.

Contact us today to discuss your application and discover how KINTEK's solutions can enhance your research or production outcomes!

Visual Guide

Related Products

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is the rotating ring disk electrode method? Unlock Real-Time Reaction Analysis

- What is the difference between RDE and RRDE? Unlock Advanced Electrochemical Reaction Analysis

- What is the common role of a platinum disk electrode? A Guide to Its Primary Use as a Working Electrode

- How should a platinum wire/rod electrode be cleaned before use? A Guide to Reliable Electrochemical Data

- What is the application of RRDE? Unlock Quantitative Catalyst and Reaction Insights