Technically, there is no fixed number of times metal can be heat treated. For processes like hardening and quenching common steels, the part can often be re-treated multiple times, provided it is properly prepared before each cycle. However, the more important question is not "how many times," but "what are the cumulative, and often negative, consequences of each cycle?"

Each heat treatment cycle is an opportunity to change a metal's properties, but it also introduces irreversible risks. The true limit is not a number, but the point at which material degradation—through carbon loss, grain growth, or distortion—makes the part unusable for its intended purpose.

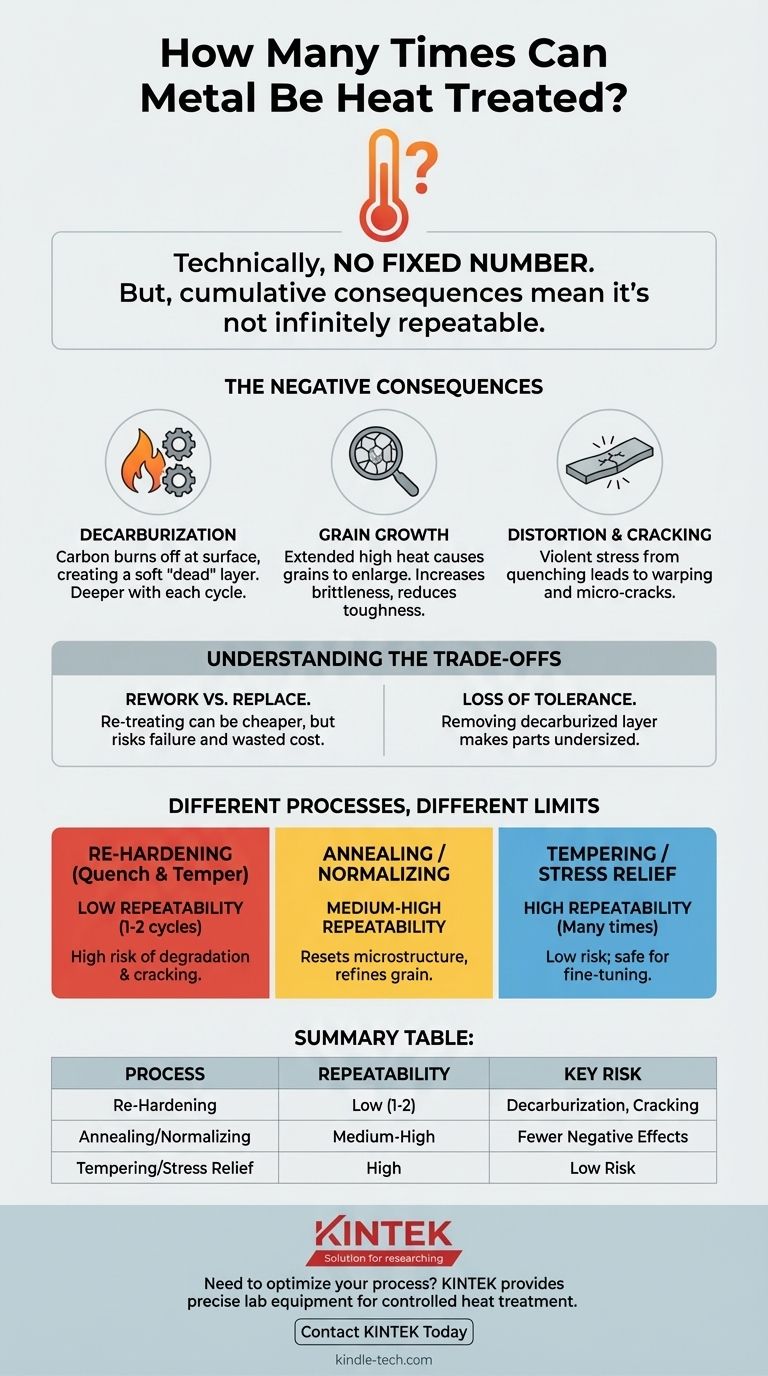

Why Heat Treatment Isn't Infinitely Repeatable

While you can repeat the steps of a heat treatment process, the material itself remembers every thermal cycle. Each trip to high temperature introduces changes, not all of which are beneficial.

The Problem of Decarburization

At hardening temperatures, the carbon at the steel's surface reacts with oxygen in the atmosphere and burns off. This process is called decarburization.

This creates a soft, "dead" layer on the surface that will not harden upon quenching. Each subsequent heat treat cycle deepens this layer, requiring more material to be ground away to reach the hardenable steel underneath.

The Risk of Grain Growth

The strength and toughness of steel are heavily influenced by its microscopic grain structure. Ideal steel has fine, tightly packed grains.

Exposing steel to high temperatures for extended periods—or through multiple cycles—can cause these grains to grow larger. Large grains lead to increased brittleness and a significant reduction in the material's toughness and impact resistance.

The Accumulation of Distortion and Cracking

Heat treating, especially quenching, is a violent process that induces massive internal stresses. Heating causes expansion, and rapid cooling causes drastic, often uneven, contraction.

Each re-hardening cycle subjects the part to this stress again. This cumulative stress increases the likelihood of warping, distortion, and the formation of micro-cracks that can lead to catastrophic failure under load.

Understanding the Trade-offs

Deciding to re-treat a part is an engineering decision with clear costs and benefits. It is never a "free" operation.

Reworking vs. Replacing

The primary trade-off is cost. Re-treating a single, complex part may be cheaper than manufacturing a new one from scratch.

However, this must be weighed against the risk. A failed re-treatment could lead to a cracked, unusable part, wasting both the original investment and the cost of the rework.

Loss of Surface Material and Tolerance

Because the decarburized layer must be removed after each hardening cycle, re-treating is not suitable for finished parts with tight dimensional tolerances.

If a part must maintain a specific size, you will likely render it undersized by grinding away the soft surface after the re-heat treatment.

The Purpose of the Retreatment

The risk profile changes based on why you are re-treating. A simple re-temper to slightly soften a part is a low-temperature, low-risk process. In contrast, a full re-hardening cycle to correct a botched quench is a high-temperature, high-risk endeavor.

Different Processes, Different Limits

The "how many times" question depends heavily on the specific heat treatment process being used.

Re-Hardening (Quench and Temper)

This is the highest-risk process to repeat. It involves austenitizing at very high temperatures, which promotes decarburization and grain growth. This should be limited to as few cycles as possible, often just one or two corrective attempts.

Annealing and Normalizing

These processes are often used to "reset" a material's microstructure, soften it for machining, or relieve internal stress. Because they involve slower cooling rates and are designed to refine grain structure, they can typically be repeated more times than hardening with fewer negative effects.

Tempering and Stress Relief

These are low-temperature processes performed after hardening. Their purpose is to reduce brittleness and relieve stress. Because they occur well below the critical transformation temperature, they can be repeated many times with virtually no harm to the steel's microstructure. It is common to re-temper a part to fine-tune its final hardness.

Making the Right Choice for Your Goal

Your decision should be based on a clear understanding of your objective and the associated risks.

- If your primary focus is to salvage a part that failed to harden: Limit yourself to a single, carefully controlled re-hardening cycle after a full anneal, and be prepared to grind away surface material.

- If your primary focus is to soften a part for re-machining: You can safely perform multiple annealing cycles, as this process is less detrimental and designed to refine the grain structure.

- If your primary focus is to adjust the final hardness of a properly hardened part: You can re-temper the part multiple times at different temperatures, as this is a low-risk process that does not degrade the material.

Ultimately, treat every heat cycle not as a simple repetition, but as a deliberate engineering decision that permanently alters the material.

Summary Table:

| Heat Treatment Process | Typical Repeatability | Key Risk of Repeating |

|---|---|---|

| Re-Hardening (Quench & Temper) | Low (1-2 corrective cycles) | High risk of decarburization, grain growth, and cracking |

| Annealing / Normalizing | Medium-High | Fewer negative effects; designed to refine grain structure |

| Tempering / Stress Relief | High (Many times) | Low risk; safe for fine-tuning hardness and relieving stress |

Need to optimize your heat treatment process and protect your valuable metal parts?

Each cycle is a critical decision that impacts material integrity. At KINTEK, we specialize in providing the precise lab equipment and consumables you need for controlled, repeatable heat treatment. Whether you are hardening, annealing, or tempering, our solutions help you achieve consistent results while minimizing material degradation.

Let our experts help you make the right call for your laboratory's needs. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the future scope of pyrolysis? Unlocking Circular Economy Potential with Waste-to-Resource Tech

- How long does it take to heat treat steel? From Hours to Days, Depending on Your Goal

- What are the factors that affect the filtration of the solution? Master the Key Variables for Optimal Performance

- What is the use of magnetron sputtering? Achieve High-Performance Thin Film Coatings

- What are the properties of sintering? Unlock Enhanced Strength and Performance

- What is magnetron sputtering coating? A High-Performance Thin Film Deposition Process

- How bio-oil can be used as energy source? Unlock Renewable Power from Biomass

- What is the high temperature variety of quartz? Unlock the Secrets of Beta-Quartz & Fused Quartz