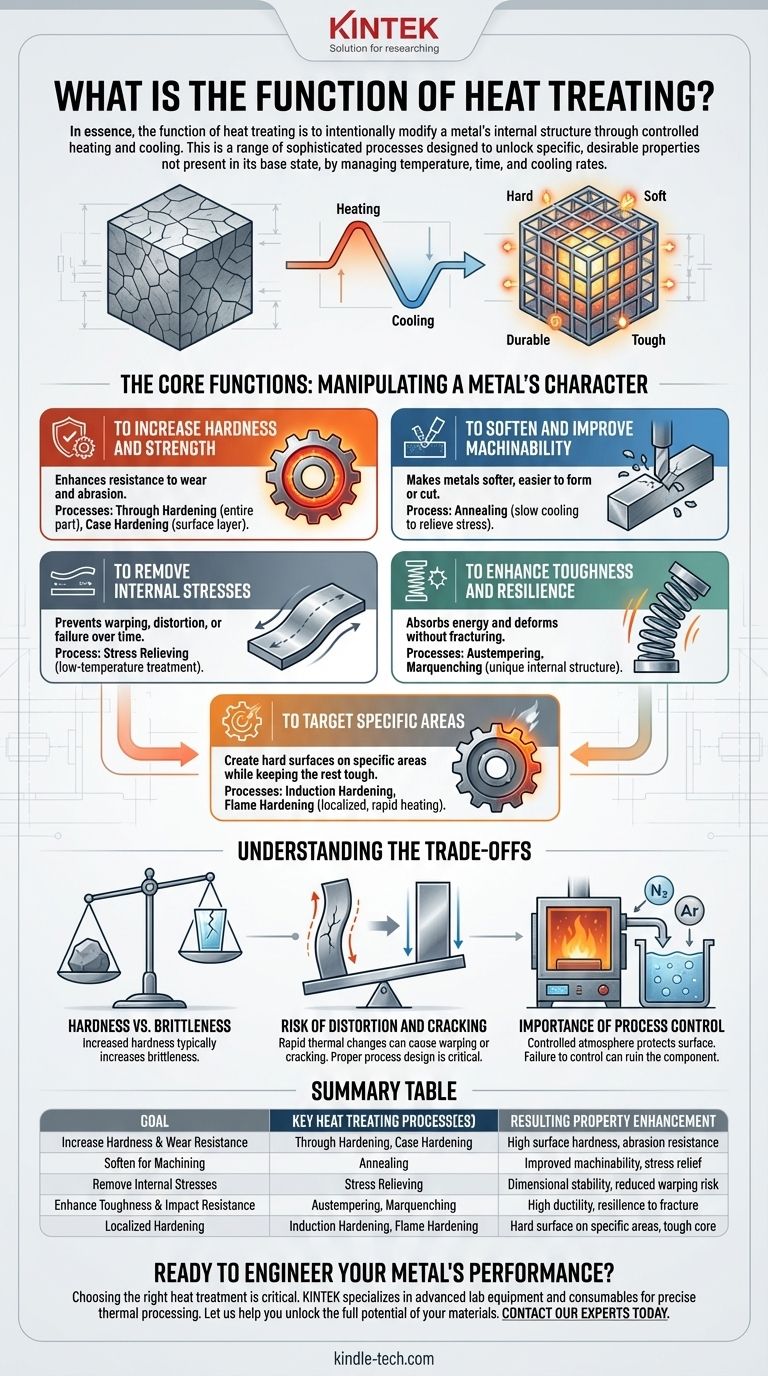

In essence, the function of heat treating is to intentionally modify a metal's internal structure through controlled heating and cooling. This is not a single action but a range of sophisticated processes designed to unlock specific, desirable properties that the metal does not possess in its base state. By carefully managing temperature, time, and cooling rates, we can make a metal harder, softer, more durable, or more resistant to stress.

Heat treating transforms a single metal alloy from a material with one set of characteristics into a platform with a wide spectrum of potential properties. The function of the process is to precisely select and lock in the exact combination of hardness, toughness, and stability required for a specific application.

The Core Functions: Manipulating a Metal's Character

Heat treatment is best understood by the problems it solves. Different processes are applied to achieve distinct, often opposing, outcomes in the final component.

To Increase Hardness and Strength

The most common goal of heat treating is to increase a metal's hardness and, consequently, its resistance to wear and abrasion. This is critical for components like gears, bearings, and cutting tools.

Processes like through hardening affect the entire part, while case hardening (e.g., carburizing or nitriding) creates an extremely hard surface layer while leaving the inner core of the metal softer and more ductile.

To Soften and Improve Machinability

Paradoxically, heat treating is also used to make metals softer. The process of annealing involves heating a metal and cooling it very slowly.

This relieves internal stresses and refines the grain structure, making the metal much easier to machine, form, or cut. It is a preparatory step to make manufacturing more efficient and less costly.

To Remove Internal Stresses

Manufacturing processes like welding, machining, and cold forming introduce significant internal stresses into a material. These hidden stresses can cause a part to warp or distort over time, or even fail unexpectedly.

Stress relieving is a low-temperature heat treatment that reduces these internal stresses without significantly changing the metal's core properties, ensuring dimensional stability.

To Enhance Toughness and Resilience

Hardness is not the same as toughness. While a hard material resists scratching, a tough material can absorb energy and deform without fracturing.

Processes like austempering and marquenching are designed to produce a unique internal structure that imparts exceptional toughness and ductility, which is ideal for components like springs and high-strength fasteners.

To Target Specific Areas

It is often undesirable to harden an entire component, as this can make it brittle. Induction hardening and flame hardening use localized, rapid heating and quenching.

This allows you to create a very hard surface in a specific area—like the teeth of a gear or the surface of a shaft—while the rest of the part remains tough and resilient.

Understanding the Trade-offs

Heat treating is a discipline of controlled compromises. Improving one property often comes at the expense of another, and improper control can introduce new problems.

The Hardness vs. Brittleness Compromise

The most fundamental trade-off in heat treating is between hardness and toughness. As a metal's hardness is increased, its brittleness typically increases as well.

An over-hardened component may resist wear perfectly, but it could shatter upon a single sharp impact. Choosing the right process involves balancing the need for wear resistance with the need for fracture resistance.

The Risk of Distortion and Cracking

The very nature of heat treating—rapid thermal expansion and contraction—puts immense stress on a component. If not managed correctly, this can lead to warping, distortion, or even catastrophic cracking during the cooling (quench) phase.

Proper process design, including pre-heating and controlled cooling rates, is critical to mitigate these risks.

The Importance of Process Control

The environment in which a part is heated is a critical variable. Using a controlled atmosphere (e.g., nitrogen, argon) is essential to protect the part's surface from oxidation and scaling at high temperatures.

This atmosphere can also be used to precisely control the surface chemistry of the steel, such as adding carbon during carburizing. Failure to control the atmosphere or quench medium can ruin the component.

Selecting the Right Treatment for Your Goal

The correct heat treatment is entirely dependent on the final application of the component. Your choice should be driven by the primary performance requirement.

- If your primary focus is maximum wear resistance: You will require a hardening process, considering case hardening if you need to maintain a tough inner core.

- If your primary focus is preparing a part for extensive machining: You should specify an annealing process to soften the material and improve workability.

- If your primary focus is ensuring stability after welding or fabrication: A stress-relief cycle is essential to prevent delayed distortion or cracking.

- If your primary focus is creating a durable, impact-resistant part: You should investigate treatments like austempering that are specifically designed to enhance toughness.

Understanding the function of heat treating empowers you to move beyond a metal's default state and engineer its properties for optimal performance.

Summary Table:

| Goal | Key Heat Treating Process(es) | Resulting Property Enhancement |

|---|---|---|

| Increase Hardness & Wear Resistance | Through Hardening, Case Hardening | High surface hardness, abrasion resistance |

| Soften for Machining | Annealing | Improved machinability, stress relief |

| Remove Internal Stresses | Stress Relieving | Dimensional stability, reduced warping risk |

| Enhance Toughness & Impact Resistance | Austempering, Marquenching | High ductility, resilience to fracture |

| Localized Hardening | Induction Hardening, Flame Hardening | Hard surface on specific areas, tough core |

Ready to Engineer Your Metal's Performance?

Choosing the right heat treatment is critical to achieving the perfect balance of hardness, toughness, and stability for your components. KINTEK specializes in providing the advanced lab equipment and consumables necessary for precise thermal processing. Whether you are developing cutting tools, durable gears, or high-strength fasteners, our solutions help you control the entire heat treatment cycle with accuracy.

Let us help you unlock the full potential of your materials. Contact our experts today to discuss how KINTEK can support your laboratory's specific heat treating needs and ensure your components perform flawlessly.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- How is hydrogen produced by pyrolysis? A Low-Carbon Alternative to Steam Reforming

- What role does a high-vacuum annealing furnace play in the preparation of platinum diffusion coatings?

- Does metal evaporate in a vacuum? Unlock the Power of Thin-Film Deposition

- Can you braze two different metals? Yes, and here’s how to do it successfully.

- What is the role of a high-temperature industrial furnace in 11% Cr steel treatment? Ensuring Structural Uniformity

- What is vacuum heating? Achieve Purity and Precision in High-Temperature Processing

- What is the purpose of using high-temperature vacuum furnaces for annealing titanium dioxide? Optimize Bioactivity

- What is the difference between combustion pyrolysis and gasification? A Guide to Thermal Conversion Technologies