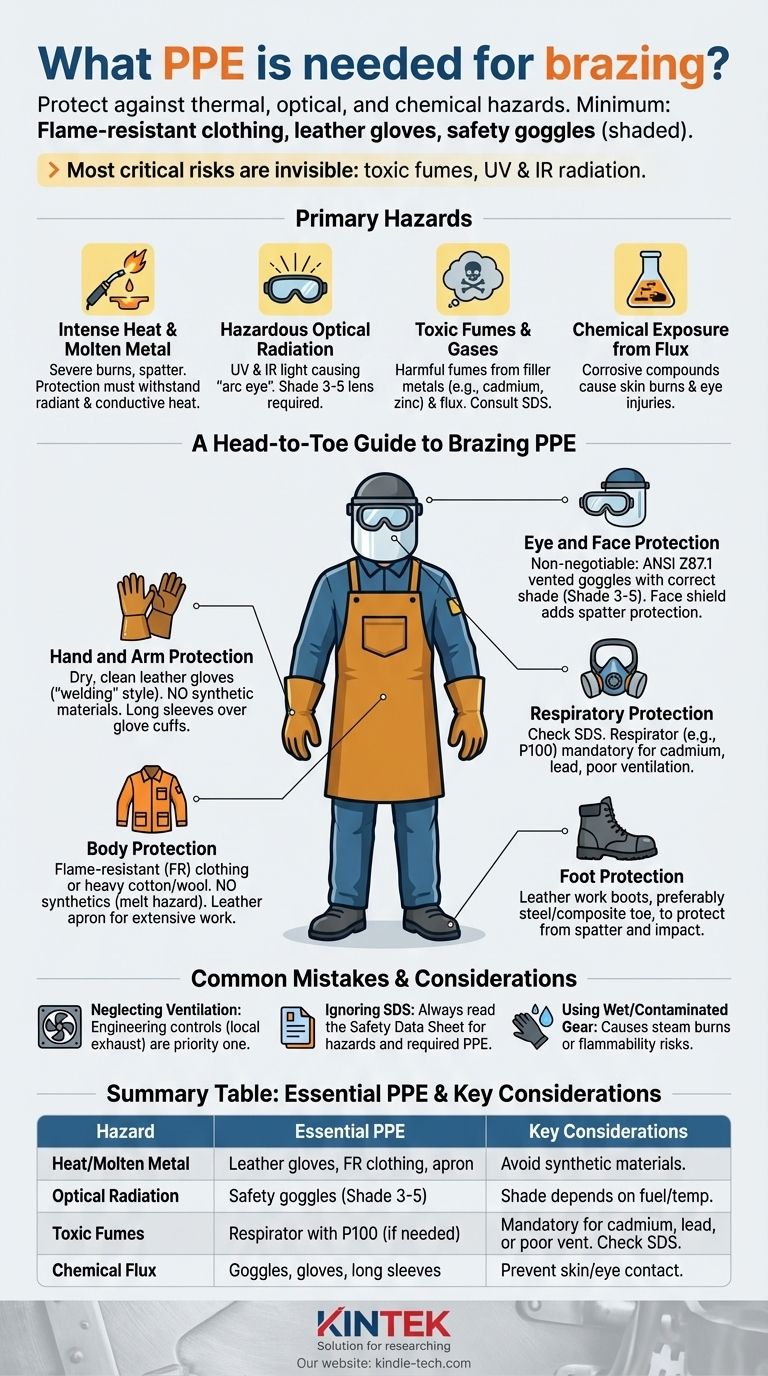

At a minimum, proper PPE for brazing includes flame-resistant clothing, leather gloves, and safety goggles with an appropriate shade rating. However, the specific type of brazing, filler metals, and work environment dictate the need for additional protection, such as respirators and face shields, to defend against the full range of thermal, optical, and chemical hazards.

Brazing safety is not just about protecting yourself from the torch's heat. The most critical, and often overlooked, risks come from invisible threats: toxic fumes from filler metals and fluxes, and harmful ultraviolet (UV) and infrared (IR) radiation from the flame.

The Primary Hazards of Brazing

To select the right PPE, you must first understand the specific dangers you are protecting against. Brazing presents a multi-faceted risk profile that extends beyond simple burns.

Intense Heat and Molten Metal

The most obvious hazard is the high temperature from the torch flame and the molten filler metal. This creates a significant risk of severe thermal burns from direct contact, spatter, or handling hot base metals.

Your PPE must be able to withstand both radiant heat from the flame and conductive heat from the workpiece.

Hazardous Optical Radiation

Brazing operations, particularly those using oxy-fuel torches, produce high-intensity visible, ultraviolet (UV), and infrared (IR) light. Prolonged exposure can cause a painful condition known as "arc eye" or "welder's flash" and can lead to long-term eye damage, including cataracts.

The required level of protection, or shade number, depends on the specific fuel gas and process being used.

Toxic Fumes and Gases

This is one of the most serious and underestimated dangers. Heating filler metals and fluxes releases fumes into the air. Many silver-brazing alloys historically contained cadmium, a highly toxic metal that can cause severe lung damage and kidney failure.

Even cadmium-free alloys can release harmful fumes from elements like zinc, copper, or silver. Fluxes can also produce irritating or toxic gases when heated. Always assume fumes are hazardous until proven otherwise.

Chemical Exposure from Flux

Brazing fluxes are chemically active compounds designed to clean base metals and are often corrosive. Direct skin contact can cause chemical burns, rashes, or dermatitis. Splashes can cause serious eye injuries.

A Head-to-Toe Guide to Brazing PPE

Your protective gear is a system. Each component is designed to counter one or more of the hazards discussed above.

Eye and Face Protection

This is non-negotiable. At a minimum, wear ANSI Z87.1-compliant safety glasses. For most tasks, vented goggles are superior as they provide a better seal against spatter and fumes.

Crucially, you must use a shaded lens. For general air-fuel brazing, a Shade 3 lens is often sufficient. For higher-temperature oxy-acetylene brazing, a Shade 4 or 5 is required. A face shield worn over goggles provides an excellent additional layer of protection from spatter.

Hand and Arm Protection

Wear dry, clean leather gloves, often labeled as "welding" or "driver's" style gloves. Leather provides excellent thermal protection and durability.

Never use synthetic gloves (nylon, polyester) as they can melt and fuse to your skin. Ensure your shirt sleeves are long and cover the cuff of the glove to prevent spatter from entering.

Body Protection

Wear flame-resistant (FR) clothing. If FR-rated garments are not available, heavy, tightly woven natural fibers like cotton denim or wool are the next best choice.

Absolutely do not wear synthetic clothing like polyester or rayon, as it can melt and cause severe burns. A leather apron or FR sleeves can provide additional protection for your torso and arms during extensive work.

Respiratory Protection

Respiratory protection is dictated by the materials used and the quality of ventilation. Always read the Safety Data Sheet (SDS) for your filler metal and flux.

If you are brazing metals containing cadmium, lead, beryllium, or working in a confined or poorly ventilated space, a respirator is mandatory. A half-mask respirator with P100 cartridges is a common choice for filtering metal fumes.

Foot Protection

Leather work boots, preferably with a steel or composite toe, are the standard. They protect your feet from sparks, spatter, and the impact of dropped tools or materials.

Understanding the Trade-offs and Common Mistakes

Selecting the right gear is only half the battle. Using it correctly and avoiding common pitfalls is what ensures your safety.

Mistake: Neglecting Ventilation

PPE is the last line of defense. Your first priority should always be engineering controls, with ventilation being the most important for brazing. Local exhaust ventilation (LEV), such as a fume extractor, is highly effective at capturing fumes at the source.

Mistake: Ignoring the Safety Data Sheet (SDS)

The SDS for your filler metal and flux is your single most important safety document. It will explicitly state the hazards, list toxic components, and specify the exact PPE required, including the type of respirator needed.

Mistake: Using Wet or Contaminated Gear

Never use wet or oily gloves or clothing. Water trapped in the material can turn to steam instantly upon contact with heat, causing a severe steam burn. Oil and other contaminants can be flammable.

Mistake: Choosing the Wrong Shade Number

Using too light a shade will not adequately protect your eyes from harmful UV/IR radiation. Using a shade that is too dark, like a standard welding helmet shade of 10+, will dangerously impair your vision of the work area, making it difficult to control the torch and filler.

Making the Right Choice for Your Goal

Select your PPE based on a risk assessment of your specific task.

- If your primary focus is simple copper plumbing with BCuP fillers: Flame-resistant or heavy cotton clothing, leather gloves, and Shade 3 safety goggles are your essential baseline.

- If your primary focus is brazing with silver alloys (check the SDS): In addition to the baseline, assess the need for a respirator and improve ventilation, especially if the alloy contains zinc or other volatile elements.

- If you are using alloys containing cadmium, lead, or other toxic metals: Mandatory use of a P100 half-mask respirator and local exhaust ventilation is required, along with full body and eye protection.

- If you are performing high-temperature torch brazing (oxy-acetylene): You must use a higher shade lens (Shade 4-5) and consider more robust body protection like a leather apron.

Effective protection is a system where proper equipment, a safe environment, and informed work practices combine to keep you safe.

Summary Table:

| Hazard | Essential PPE | Key Considerations |

|---|---|---|

| Intense Heat & Molten Metal | Leather gloves, FR clothing, leather apron | Avoid synthetic materials that can melt. |

| Optical Radiation (UV/IR) | Safety goggles with correct shade (Shade 3-5) | Shade number depends on fuel gas and temperature. |

| Toxic Fumes & Gases | Respirator with P100 cartridges (if needed) | Mandatory for cadmium, lead, or poor ventilation. Check SDS. |

| Chemical Flux Exposure | Goggles, gloves, long sleeves | Prevent direct skin and eye contact with corrosive flux. |

Protect your team and optimize your brazing process with confidence. The right safety gear is crucial for any laboratory or workshop. KINTEK specializes in providing reliable lab equipment and consumables to support safe and efficient operations. Whether you need guidance on selecting the appropriate PPE or are outfitting your entire lab, our experts are here to help.

Contact us today to discuss your specific brazing safety needs and discover how KINTEK can be your trusted partner in laboratory safety and efficiency.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Vacuum Cold Trap Direct Cold Trap Chiller

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating