The duration of a heat treatment cycle is not a single number; it ranges from under an hour for small, simple parts to several days for large, complex components. The final time is dictated by a precise recipe involving the material type, the component’s mass and thickness, and the specific mechanical properties you need to achieve.

The total time for heat treatment is less about how fast a furnace can get hot and more about soaking—the critical holding period required for the part's thickest section to achieve a complete and uniform internal transformation.

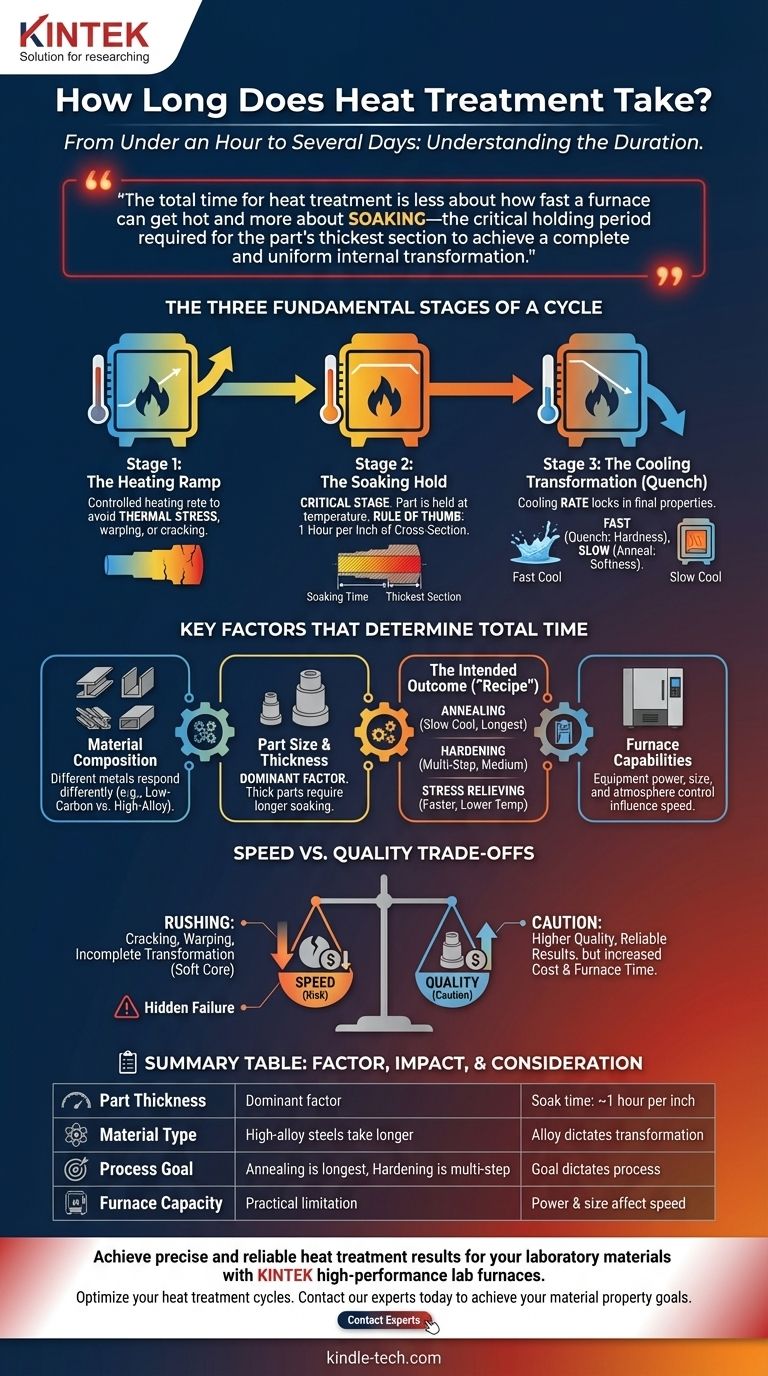

The Three Fundamental Stages of Any Heat Treatment Cycle

To understand the total duration, you must first understand that every cycle consists of three distinct stages. The time required for each stage is calculated based on specific metallurgical goals.

Stage 1: The Heating Ramp

This is the initial phase of bringing the material up to a target temperature. While it may seem simple, the rate of heating is critical.

Heating a part too quickly can induce thermal stress, causing warping or even cracking, especially in complex geometries. The ramp time is carefully controlled to ensure the entire part heats as uniformly as possible.

Stage 2: The Soaking Hold

Once at temperature, the part is "soaked" or held for a specific duration. This is often the most critical and time-consuming stage.

The purpose of soaking is to allow the material's internal crystal structure to fully transform. For steel, this means ensuring the entire part, from surface to core, has converted to austenite. The standard rule of thumb is to soak for one hour for every inch of cross-sectional thickness, but this can vary based on the alloy.

Stage 3: The Cooling Transformation (Quench)

The final stage is cooling the part back to room temperature. The cooling rate is the most important variable here, as it locks in the final properties.

This can be extremely fast (a quench in water or oil lasting minutes) to achieve hardness, or extremely slow (letting the part cool down in the furnace over many hours or days) to achieve maximum softness, as in annealing.

Key Factors That Determine Total Time

Several variables interact to define the "recipe" and, therefore, the duration of the heat treatment process.

Material Composition and Type

Different metals and alloys respond to heat at different rates. A simple low-carbon steel will have a very different time requirement than a high-alloy tool steel or a non-ferrous material like an aluminum alloy undergoing age hardening.

Part Size and Cross-Sectional Thickness

This is the single most dominant factor. A thin sheet metal part might be heated and soaked in minutes. A massive forging or die block, several feet thick, will require many hours—or even days—to ensure its core reaches the same temperature and transformation state as its surface.

The Intended Outcome (The "Recipe")

The goal dictates the process, which in turn dictates the time.

- Annealing (Softening): Requires very slow cooling, often making it one of the longest processes.

- Hardening (Quenching & Tempering): Involves a fast quench followed by a second, lower-temperature heating cycle (tempering) to reduce brittleness. It's a two-step process.

- Stress Relieving: Typically uses lower temperatures and shorter soak times, making it a comparatively faster operation.

Furnace and Equipment Capabilities

Practical limitations also play a role. The size of the furnace, its heating power, its cooling capabilities, and the atmosphere control (e.g., vacuum or inert gas) all influence how quickly and accurately a specific cycle can be executed.

Understanding the Trade-offs: Speed vs. Quality

Attempting to shorten heat treatment cycles without understanding the metallurgical consequences is a common and costly mistake.

The Risk of Rushing: Cracking and Warping

The most immediate danger of heating or cooling too quickly is thermal shock. When the surface of a part changes temperature much faster than its core, the resulting internal stresses can cause permanent distortion (warping) or catastrophic failure (cracking).

The Cost of Caution: Furnace Time and Throughput

The primary trade-off is economic. A longer, more conservative cycle provides a higher-quality, more reliable result but consumes more energy and furnace time. This directly impacts project cost and manufacturing throughput.

Incomplete Transformation: The Hidden Failure

Cutting the soak time is a frequent temptation. However, if the core of the part does not fully transform, you will have a component with a hard surface but a soft, weak interior. This can lead to unexpected field failures despite the part passing a superficial hardness test.

Making the Right Choice for Your Goal

To estimate the time required, always start with the desired outcome and the component's thickest section.

- If your primary focus is maximum hardness (e.g., for a cutting tool): Plan for a multi-stage process of hardening and tempering, where total time is influenced by both the initial soak and the subsequent tempering cycles.

- If your primary focus is maximum softness and machinability (annealing): Expect a very long cycle, as the critical factor is the extremely slow, controlled cooling rate inside the furnace.

- If your primary focus is simply removing stress from welding or machining: This is often the fastest process, as it occurs at lower temperatures and doesn't require a full structural transformation.

- If you are working with very large or thick components: The soaking time, calculated based on the thickest cross-section, will dominate the entire schedule and should be the central point of your planning.

Understanding these variables transforms heat treatment from a black box into a predictable and controllable engineering process.

Summary Table:

| Factor | Impact on Duration | Key Consideration |

|---|---|---|

| Part Thickness | Dominant factor | Soak time: ~1 hour per inch of thickness |

| Material Type | High-alloy steels take longer | Alloy composition dictates transformation rate |

| Process Goal | Annealing (slow cool) is longest | Hardening & tempering is a multi-step process |

| Furnace Capacity | Practical limitation | Heating/cooling power and size affect cycle speed |

Achieve precise and reliable heat treatment results for your laboratory materials.

At KINTEK, we specialize in supplying high-performance lab furnaces and equipment designed for exacting thermal processes. Whether you are annealing for softness, hardening for durability, or stress-relieving complex components, our solutions ensure uniform heating and controlled cooling for consistent, high-quality outcomes.

Let us help you optimize your heat treatment cycles. Contact our experts today to discuss your specific laboratory equipment needs and achieve your material property goals.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the necessity of a high-temperature calcination process in the synthesis of CoWO4 nanomaterials? Unlock Purity

- Why use a constant temperature oven for fluoride ion battery testing? Ensure Precise EIS and CV Data Integrity

- What is the ashing method of muffle furnace? A Guide to Accurate Sample Analysis

- What conditions does a muffle furnace provide for c-LLZO nanopowders? Achieve Pure Phase Synthesis at 750°C

- What is the role of the high-temperature furnace in preparing BZCY ceramic? Master Phase Formation and Purity

- What is the function of a solution treatment furnace? Activating CuAlMn Shape Memory Alloys

- What role does a high-temperature muffle furnace play in the fusion-hydrothermal synthesis of Coal Fly Ash Zeolite?

- What is the mechanism of a laboratory oven? Master Precise Temperature Control for Your Lab