In essence, the purpose of the full annealing process is to make a metal, typically steel, as soft and ductile as possible. This heat treatment effectively reverses the hardening and brittleness caused by processes like cold working or forging, relieving internal stresses and creating a uniform, easily workable microstructure.

Full annealing is not just about softening a metal; it is a precise metallurgical process designed to achieve a specific, stress-free equilibrium state. By heating steel above its critical temperature and then cooling it extremely slowly, you create a coarse pearlite structure that offers maximum ductility and machinability.

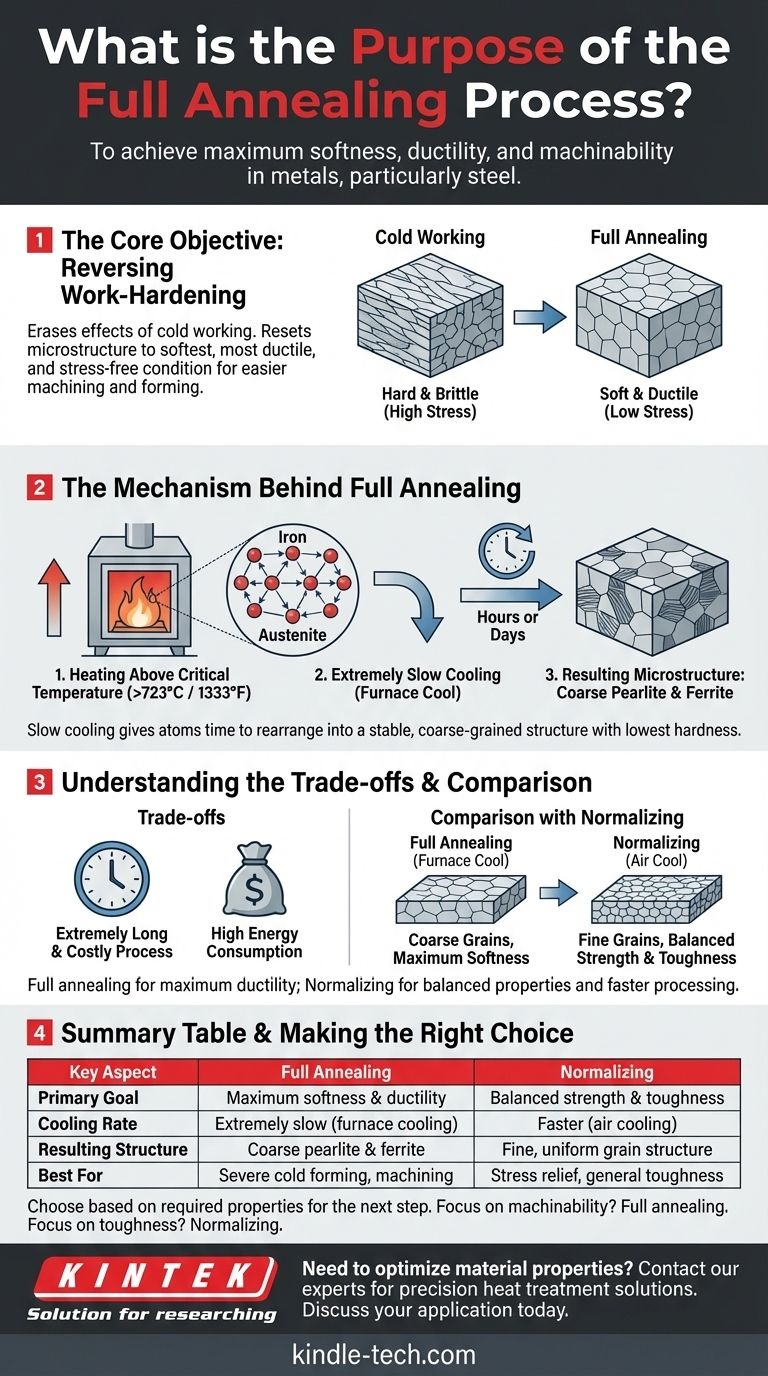

The Core Objective: Reversing Work-Hardening

Why Materials Become Hard and Brittle

When a metal is mechanically shaped at room temperature (a process known as cold working), its internal crystal structure, or "grains," becomes distorted and strained.

This process, called work-hardening, increases the material's hardness and strength but significantly reduces its ductility, making it brittle and prone to cracking if further work is attempted.

The Goal of Maximum Softness

Full annealing is employed to completely erase the effects of work-hardening.

The primary goal is to "reset" the material's microstructure to its softest, most ductile, and stress-free condition. This makes the metal easier to machine, shape, or form without failure.

The Mechanism Behind Full Annealing

Heating Above the Critical Temperature

The process begins by heating the steel to a specific temperature, typically well above 723°C (1333°F), into a region where its crystalline structure transforms entirely into a phase called austenite.

In this austenitic state, the previous distorted grain structure is completely erased, forming a uniform, solid solution.

The Importance of Extremely Slow Cooling

This is the defining step of full annealing. The material is cooled down very slowly, often by simply turning off the furnace and letting it cool over many hours or even days.

This controlled, slow cooling rate gives the atoms ample time to rearrange themselves into a highly ordered and coarse-grained microstructure.

The Resulting Microstructure

As the steel slowly cools, the austenite transforms into a mixture of ferrite (pure iron) and pearlite (a layered structure of ferrite and iron carbide).

This coarse ferrite and pearlite structure is stable, has very low internal stress, and corresponds to the lowest possible hardness and highest possible ductility for that steel.

Understanding the Trade-offs

Time and Cost

The primary drawback of full annealing is that it is an extremely long and costly process. The requirement for slow furnace cooling means a furnace is occupied for an extended period, leading to high energy consumption and low throughput.

Comparison with Normalizing

Normalizing is a similar heat treatment where steel is heated to the austenitic range but is then cooled in still air. This faster cooling rate is less expensive and time-consuming.

Annealed vs. Normalized Properties

Air cooling (normalizing) produces a finer, more uniform grain structure compared to the coarse grains of full annealing.

A normalized part is consequently harder, stronger, and tougher than a fully annealed one. Full annealing provides maximum softness, while normalizing provides a more balanced set of mechanical properties.

Making the Right Choice for Your Goal

Your choice between full annealing and other treatments depends entirely on the required properties for the next manufacturing step or the final application.

- If your primary focus is maximum machinability or extensive cold forming: Choose full annealing, as it produces the softest possible state, which reduces tool wear and prevents cracking during severe deformation.

- If your primary focus is relieving stress with improved toughness: Consider normalizing, as it is a more economical process that delivers a refined grain structure with a good balance of strength and ductility.

- If your primary focus is reducing the brittleness of an already-hardened part: You need tempering, a lower-temperature process that follows quenching to increase toughness.

Ultimately, controlling a material's final properties comes from understanding how heat and time can fundamentally reshape its internal structure.

Summary Table:

| Key Aspect | Full Annealing | Normalizing |

|---|---|---|

| Primary Goal | Maximum softness & ductility | Balanced strength & toughness |

| Cooling Rate | Extremely slow (furnace cooling) | Faster (air cooling) |

| Resulting Structure | Coarse pearlite & ferrite | Fine, uniform grain structure |

| Best For | Severe cold forming, machining | Stress relief, general toughness |

Need to optimize your material's properties for machining or forming?

At KINTEK, we specialize in precision heat treatment solutions for laboratories and manufacturing. Whether you require full annealing for maximum ductility or other processes like normalizing for balanced properties, our expertise and high-quality lab equipment ensure you achieve the exact material characteristics your project demands.

Let's discuss your application: Contact our experts today to find the ideal heat treatment strategy for your steel or other metals.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the debinding process? A Guide to Critical Binder Removal for MIM & 3D Printing

- What is the use of muffle furnace in soil? Analyze Soil Composition with High-Temperature Precision

- What does a lab muffle furnace do? Achieve Pure, Contamination-Free Heating for Your Lab

- How to use a muffle furnace in a laboratory? A Step-by-Step Guide to Safe, Precise Thermal Processing

- What is the maximum temperature of a muffle furnace? Find the Right Heat for Your Application