The source of heat for brazing is not one single method, but rather a range of technologies chosen based on the application's specific needs. The most common heat sources are fuel-gas torches, controlled atmosphere furnaces, and high-frequency induction coils, each offering a unique balance of speed, precision, and cost. Other specialized methods include resistance, dip, and infrared brazing.

The critical insight is that your choice of a heat source is not about preference, but a strategic decision. The method you choose directly dictates the quality of the final joint, the speed of production, and the overall cost of your operation.

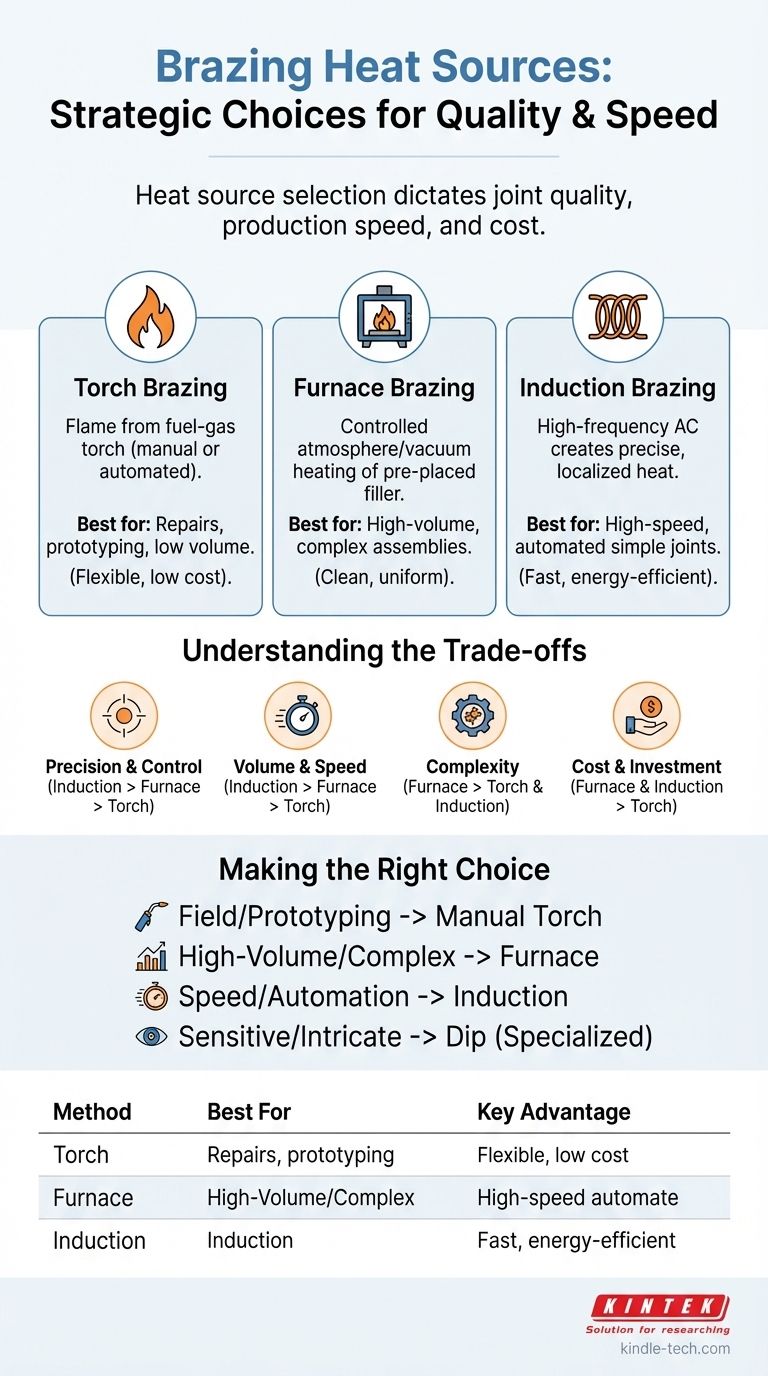

An Overview of Common Brazing Heat Sources

Each heating method has distinct characteristics that make it suitable for different materials, joint configurations, and production volumes. Understanding these is key to a successful brazing process.

Torch Brazing

Torch brazing is the most common and versatile method. It uses the flame from a gas-fueled torch (such as oxy-acetylene, propane, or natural gas) to heat the parts and melt the filler metal.

This method can be performed manually by a skilled operator, making it ideal for repairs, prototyping, and low-volume production due to its low initial cost and portability. It can also be automated with fixed torches or robotic arms for higher-volume, repetitive tasks.

Furnace Brazing

In furnace brazing, parts are assembled with the filler metal pre-placed at the joint. The entire assembly is then heated to brazing temperature inside a furnace.

This process is almost always performed in a controlled atmosphere (like nitrogen or hydrogen) or a vacuum to prevent oxidation. This often eliminates the need for flux, resulting in exceptionally clean and high-quality joints. It is the preferred method for high-volume production and complex assemblies with multiple joints.

Induction Brazing

Induction brazing uses a high-frequency alternating current passed through a copper coil. This creates a magnetic field that induces an electrical current within the metal parts, generating precise and rapid heat exactly where it is needed.

Because the heating is so fast and localized, induction is extremely energy-efficient and ideal for high-volume, automated production of simple, repetitive joints. The design of the induction coil is critical and must be tailored to the specific geometry of the part.

Other Specialized Methods

While less common, other methods serve specific industrial needs.

Dip brazing involves immersing the assembly into a bath of molten salt flux or molten filler metal, ensuring rapid and uniform heating. Resistance brazing uses electrodes to pass a high electrical current through the assembly, generating heat via the parts' natural electrical resistance.

Understanding the Trade-offs

Choosing the right heat source requires balancing four critical factors: control, volume, complexity, and cost. Misunderstanding these trade-offs is a common source of brazing failures.

Precision and Heat Control

Induction brazing offers the highest level of control, delivering precise, repeatable heat to a very small area. Furnace brazing provides the most uniform heating across an entire, complex part.

Manual torch brazing relies entirely on operator skill and is the most susceptible to inconsistent heating, overheating, or under-heating, which can compromise the joint's integrity.

Production Volume and Speed

For maximum speed in high-volume production, nothing beats induction brazing, where heating cycles can be a matter of seconds. Furnace brazing is also excellent for high volumes, as many parts can be processed simultaneously in a single batch.

Torch brazing is generally slower and better suited for one-off jobs or low-volume work where setup time for other methods would be impractical.

Joint and Material Complexity

Furnace brazing excels with complex assemblies that have multiple or inaccessible joints, as the entire part is heated uniformly. It is also ideal for materials that are highly sensitive to localized heat stress.

Torch and induction brazing are best for simpler, easily accessible joints where heat can be applied directly.

Cost and Initial Investment

Torch brazing has the lowest initial equipment cost, making it accessible for nearly any operation.

Furnace and induction systems represent a significant capital investment. Their cost is justified by the high throughput, reduced labor, and superior quality they deliver in demanding production environments.

Making the Right Choice for Your Application

Selecting a heat source is a technical decision that should be driven by the goals of your project.

- If your primary focus is field repair, prototyping, or low-volume work: Manual torch brazing offers the best combination of portability, flexibility, and low initial cost.

- If your primary focus is high-volume production of complex parts: Furnace brazing provides unparalleled joint quality, cleanliness, and consistency at scale.

- If your primary focus is speed and automation on simple, repetitive joints: Induction brazing delivers exceptional speed, precision, and energy efficiency for mass production.

- If you are working with sensitive or intricate aluminum assemblies: Dip brazing may be the most effective method for ensuring complete, uniform heat transfer.

Ultimately, understanding how each heat source interacts with your materials and production goals is the foundation for creating consistently strong and reliable brazed joints.

Summary Table:

| Brazing Method | Best For | Key Advantage |

|---|---|---|

| Torch Brazing | Repairs, prototyping, low volume | Low cost, high flexibility |

| Furnace Brazing | High volume, complex assemblies | Superior joint quality & uniformity |

| Induction Brazing | High-speed, automated production | Precise, localized, energy-efficient heating |

Unsure which brazing heat source is right for your application? The experts at KINTEK can help. We specialize in providing the ideal lab equipment and consumables for your specific brazing and material joining challenges.

Whether you need a robust furnace for high-volume production or precise tools for R&D, we have the solutions to enhance your process efficiency and joint quality.

Contact our technical team today for a personalized consultation and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the different types of brazing welding? A Guide to Choosing the Right Heat Source

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries