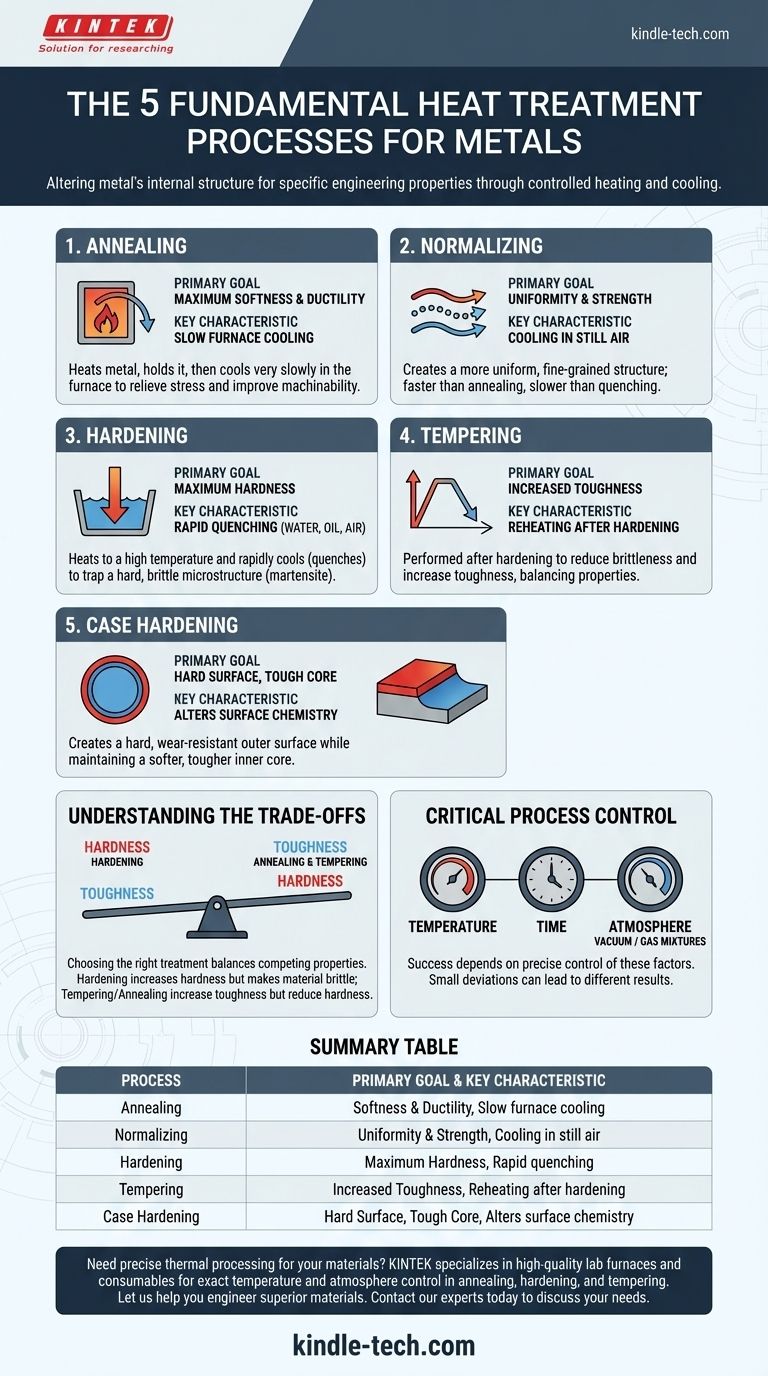

To be precise, the five most fundamental heat treatment processes for metals are annealing, normalizing, hardening, tempering, and case hardening. Each process involves a specific cycle of heating and cooling designed to deliberately alter a metal's internal structure, thereby changing its physical properties like strength, hardness, and ductility to meet a specific engineering requirement.

The core purpose of heat treatment is not just to heat metal, but to precisely control its internal crystalline structure. By managing temperature, time, and cooling rates, you can tailor a metal's properties to achieve a desired balance between hardness and toughness for a specific application.

The Goal: Manipulating Metal Microstructure

Heat treatment works by transforming the microscopic crystal structure, or microstructure, within a metal. Heating allows these crystals to change their formation, and the speed of cooling locks in a specific structure, which in turn dictates the material's macroscopic properties.

Annealing: For Maximum Softness and Ductility

Annealing is a process used to make a metal as soft and ductile as possible. This is often done to relieve internal stresses, improve machinability, or prepare the material for further forming operations.

The process involves heating the metal to a specific temperature, holding it there for a period, and then cooling it very slowly, typically inside the furnace itself. This slow cooling allows the internal grains to grow large and uniform, resulting in a soft, low-stress state.

Normalizing: For Uniformity and Strength

Normalizing is often confused with annealing, but its purpose is different. It aims to create a more uniform and fine-grained microstructure, which removes internal stresses while providing a predictable level of hardness and strength.

The key difference is the cooling rate. After heating, the metal is removed from the furnace and cooled in still air. This is faster than furnace cooling (annealing) but slower than quenching (hardening), resulting in a material that is slightly harder and stronger than an annealed one but still easily machinable.

Hardening: For Maximum Hardness and Wear Resistance

Hardening is used to make steel significantly harder and more resistant to wear. This is essential for applications like cutting tools, bearings, and structural components that must withstand high loads.

The process involves heating the steel to a high temperature to transform its microstructure, followed by a rapid cooling process called quenching. Quenching is typically done in water, oil, or air, and this rapid cooling "traps" the steel in a very hard but also very brittle crystalline state known as martensite.

Tempering: For Increasing Toughness

A hardened part is often too brittle for practical use; a sharp impact could cause it to shatter. Tempering is a secondary process performed immediately after hardening to reduce this brittleness and increase toughness.

The hardened part is reheated to a much lower temperature, held for a specific time, and then cooled. This process relieves some of the internal stress and allows the brittle martensite structure to transform slightly, trading a small amount of hardness for a significant gain in toughness and impact resistance.

Case Hardening: For a Tough Core and Hard Surface

Case hardening, also known as surface hardening, creates a component with two distinct zones: a hard, wear-resistant outer surface (the "case") and a softer, tougher inner core. This is ideal for parts like gears and shafts that need to resist surface wear while also withstanding impacts without fracturing.

Processes like carburizing (adding carbon to the surface) are used to change the chemical composition of the outer layer before it undergoes a hardening and tempering cycle, affecting only the surface while the core remains ductile.

Understanding the Trade-offs

Choosing the right heat treatment is a matter of balancing competing properties. It is impossible to maximize all desirable traits simultaneously.

The Hardness vs. Toughness Dilemma

The most fundamental trade-off in heat treatment is between hardness and toughness.

- Hardening creates extreme strength and wear resistance but makes the material brittle (low toughness).

- Tempering and Annealing increase toughness and ductility but reduce the material's overall hardness and strength.

The final combination of hardening and tempering is a carefully calculated compromise to achieve the optimal performance for the intended application.

The Critical Role of Process Control

The success of any heat treatment depends on precise control over three factors: temperature, time, and atmosphere.

Small deviations in furnace temperature or the rate of cooling can lead to drastically different results. Furthermore, as noted in advanced applications, controlling the furnace atmosphere (e.g., using a vacuum or specific gas mixtures) is critical to prevent unwanted surface reactions like oxidation on the finished part.

Making the Right Choice for Your Application

Your final selection depends entirely on the engineering goal for the component.

- If your primary focus is machinability or stress relief: Choose annealing for maximum softness or normalizing for a more uniform structure.

- If your primary focus is extreme wear resistance on a surface: Case hardening is the correct approach to create a hard exterior with a tough core.

- If your primary focus is high strength and impact durability: A combination of hardening (via quenching) followed by tempering is the standard path for tools and structural parts.

- If your primary focus is preparing a metal for a subsequent forming process: Annealing is used to make the material ductile and easy to shape.

Ultimately, heat treatment transforms a standard piece of metal into a high-performance component engineered for a specific task.

Summary Table:

| Process | Primary Goal | Key Characteristic |

|---|---|---|

| Annealing | Softness & Ductility | Slow furnace cooling |

| Normalizing | Uniformity & Strength | Cooling in still air |

| Hardening | Maximum Hardness | Rapid quenching |

| Tempering | Increased Toughness | Reheating after hardening |

| Case Hardening | Hard Surface, Tough Core | Alters surface chemistry |

Need precise thermal processing for your materials?

The right heat treatment is critical for achieving the perfect balance of hardness, strength, and toughness in your metal components. KINTEK specializes in providing the high-quality lab furnaces and consumables necessary for exact temperature and atmosphere control in processes like annealing, hardening, and tempering.

Let us help you engineer superior materials. Contact our experts today to discuss your specific laboratory equipment needs and ensure your heat treatment processes deliver consistent, reliable results.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- How does a heat treatment furnace work? Master Precise Thermal Cycles for Superior Material Properties

- What is the maximum temperature of a heat treatment furnace? From 1100°C to 2200°C+

- What is the role of vacuum in deposition? Enabling High-Purity, Controlled Thin-Film Processes

- Why is a vacuum drying oven utilized for AlCrFeNiTix powders? Prevent Oxidation & Preserve High-Entropy Alloy Purity

- What is the significance of maintaining a high vacuum environment during the sintering of ODS iron-based alloys?

- What is the primary function of a vacuum drying oven in the preparation of PANI nanotubes? Protect Polymer Integrity

- What is the temperature of a calcination furnace? Precise Control from 800°C to 1300°C

- What function does a vacuum drying oven serve in HSE and NaFePO4 production? Enhance Battery Stability and Purity