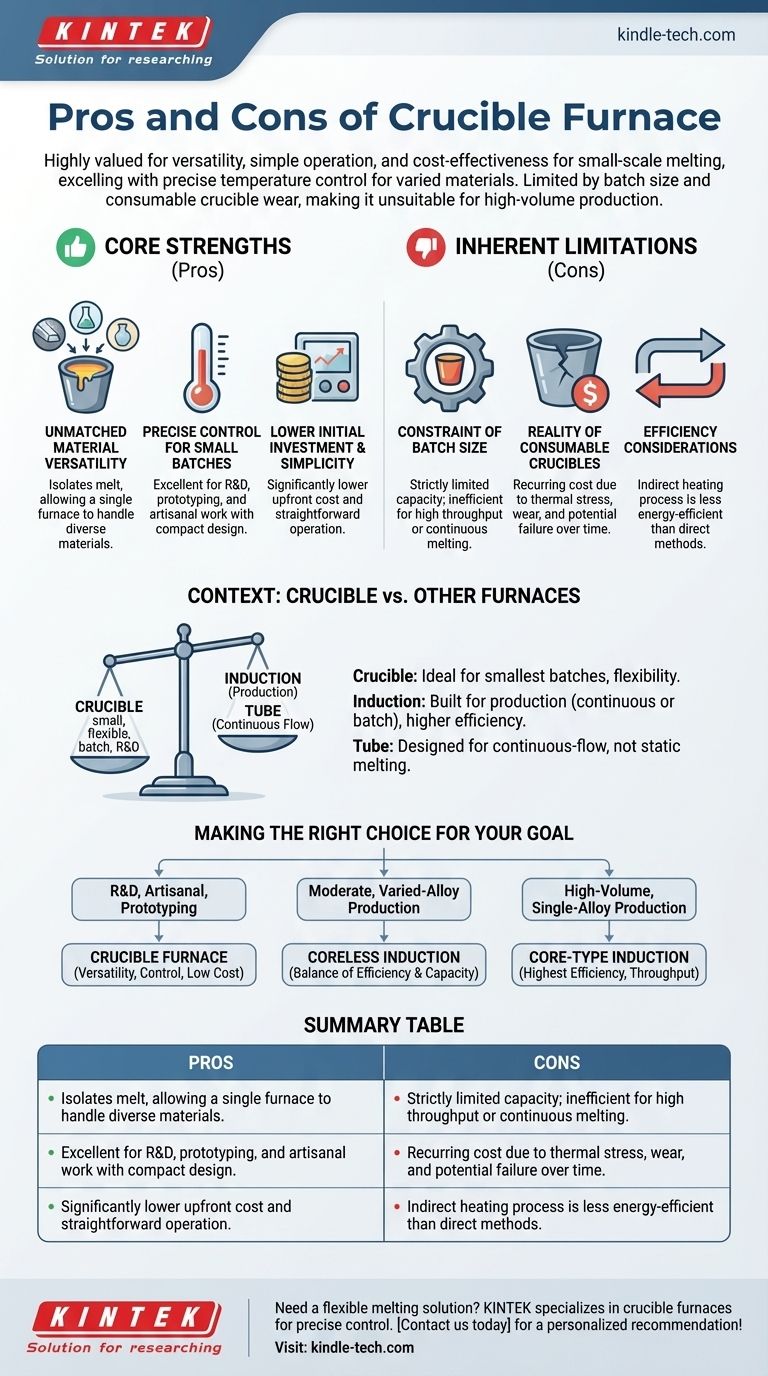

In short, a crucible furnace is highly valued for its versatility, simple operation, and cost-effectiveness for small-scale melting. It excels at handling a wide variety of materials with precise temperature control. However, its primary drawbacks are a limited batch size and the ongoing operational cost and maintenance associated with crucible wear and tear, making it unsuitable for high-volume production.

The decision to use a crucible furnace is not about whether it is "good" or "bad," but whether its specific strengths align with your operational scale. It is the definitive choice for flexibility and small batches, but gives way to other technologies as production volume increases.

The Core Strengths of a Crucible Furnace

A crucible furnace’s design is fundamentally simple: a heating chamber and a removable container (the crucible). This simplicity is the source of its primary advantages.

Unmatched Material Versatility

Because the material being melted is contained entirely within the inert crucible, there is no direct contact with the furnace's heating elements.

This isolation allows a single furnace to melt a vast range of materials, including various metals, alloys, glass, and even ceramics, simply by using the appropriate crucible.

Precise Control for Small Batches

Crucible furnaces offer excellent temperature control, which is critical for metallurgical research, prototyping, and artisanal work where material properties are paramount.

Their typically compact size makes them ideal for laboratories, small foundries, and workshops that do not require continuous, large-scale output.

Lower Initial Investment and Simplicity

Compared to more complex industrial systems like induction furnaces, a crucible furnace represents a significantly lower upfront cost.

Their operation is straightforward, requiring less specialized training to manage melting cycles, making them highly accessible for smaller operations.

The Inherent Limitations

The same design that provides flexibility also creates clear operational boundaries. Understanding these is key to avoiding a mismatched investment.

The Constraint of Batch Size

The furnace's capacity is strictly limited by the size of the crucible it can hold. This makes it inherently a batch-process tool.

It is inefficient and impractical for applications requiring high throughput or the continuous melting of large quantities of metal.

The Reality of Consumable Crucibles

The crucible itself is a consumable item. It is subjected to extreme thermal stress and chemical interaction, leading to inevitable wear, cracking, or failure over time.

This wear represents a recurring operational cost and requires careful inspection and inventory management to prevent catastrophic failures and production downtime. Crucibles are most commonly made of graphite, clay, or silicon carbide.

Efficiency Considerations

The efficiency of a crucible furnace can vary depending on the design and the material being melted. Heat is transferred from the heating elements to the crucible and then into the charge material.

This indirect heating process can be less energy-efficient than methods like induction heating, where the material itself is heated directly by an electromagnetic field.

Context is Key: Crucible vs. Other Furnaces

A crucible furnace's value becomes clear when compared to other common industrial furnaces. Each is designed for a different purpose.

Crucible vs. Induction Furnaces

Induction furnaces are built for production. Core-type induction furnaces boast efficiencies up to 98% but must run continuously, making them ideal for high-volume, single-alloy foundries.

Coreless induction furnaces are more flexible—they can be stopped and started—but are still much larger and more efficient (around 75%) than a crucible furnace, positioning them as a step-up for moderate production needs with varied alloys. A crucible furnace sits below both in scale, offering maximum flexibility for the smallest batches.

Crucible vs. Tube Furnaces

Tube furnaces are designed for continuous-flow processes, not static melting. Materials pass through a heated tube, making them suitable for processes like chemical cracking or annealing wires.

A crucible furnace is for melting a static, contained batch of material. The two technologies solve fundamentally different problems and are rarely interchangeable.

Making the Right Choice for Your Goal

Selecting the correct furnace requires a clear understanding of your primary operational goal.

- If your primary focus is R&D, artisanal work, or prototyping: A crucible furnace is the ideal choice due to its unmatched versatility, precise control, and low initial cost.

- If your primary focus is moderate, varied-alloy production: A coreless induction furnace offers a better balance of efficiency and capacity for a dedicated production environment.

- If your primary focus is high-volume, continuous production of one alloy: A core-type induction furnace provides the highest efficiency and throughput but demands a near-constant operational schedule.

By aligning the technology's inherent trade-offs with your specific goals, you can confidently select the right melting solution for your needs.

Summary Table:

| Pros | Cons |

|---|---|

| Unmatched material versatility (metals, glass, ceramics) | Limited batch size, not for high-volume production |

| Precise temperature control for R&D and prototyping | Consumable crucibles add recurring cost and maintenance |

| Lower initial investment and simple operation | Less energy-efficient than induction heating methods |

| Ideal for labs, small foundries, and workshops | Requires careful crucible inspection to prevent failures |

Need a flexible melting solution for your lab or small-scale production? KINTEK specializes in crucible furnaces and lab equipment, offering the precise control and versatility your projects demand. Let our experts help you select the right furnace for your specific materials and batch size. Contact us today to discuss your application and get a personalized recommendation!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?