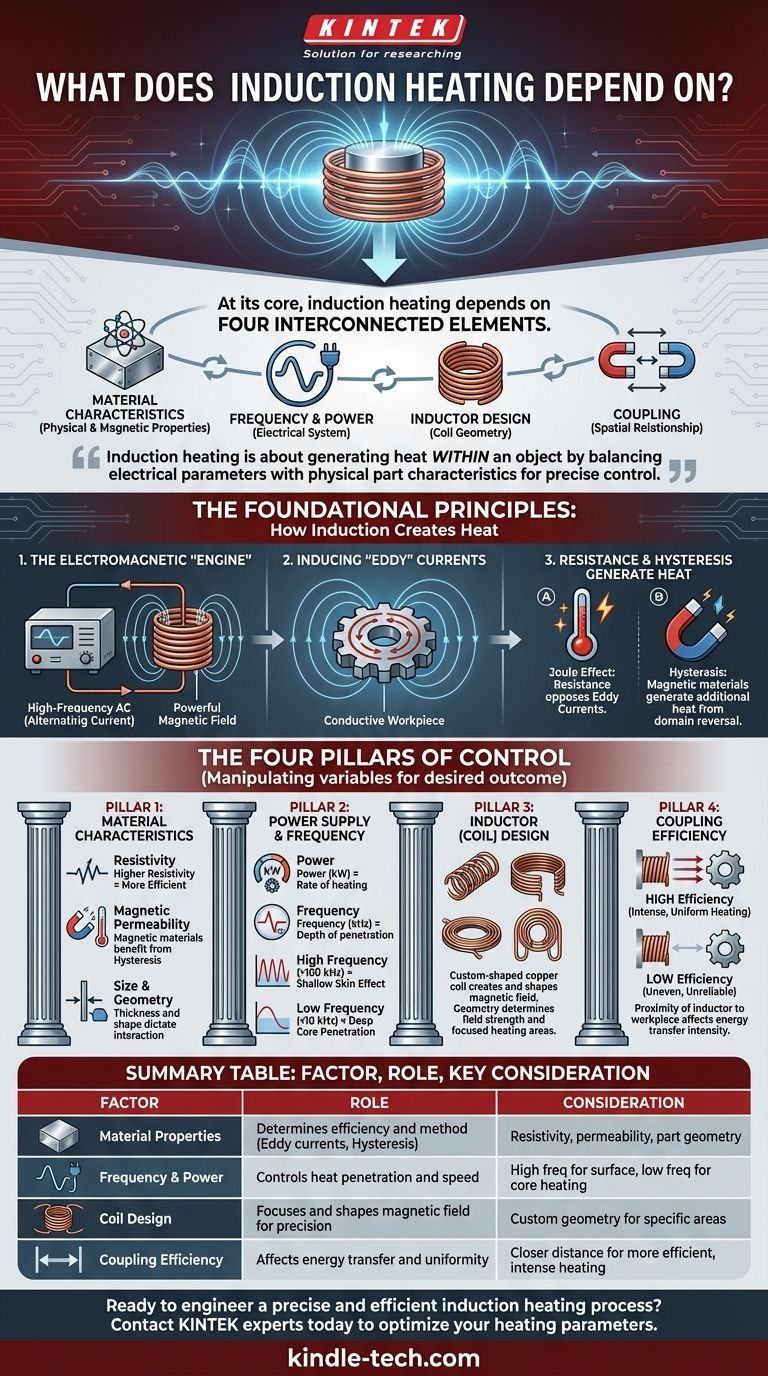

At its core, induction heating depends on four interconnected elements. These are the physical and magnetic properties of the material being heated, the frequency and power of the electrical system, the geometric design of the induction coil, and the spatial relationship, or "coupling," between the coil and the material. The process works by inducing electrical currents directly inside the part, allowing for rapid, non-contact heating.

Induction heating is not about applying external heat; it is about generating heat within an object. Success depends on balancing the electrical parameters of the system with the physical characteristics of the part to control precisely where and how quickly this internal heat is generated.

The Foundational Principles: How Induction Creates Heat

To control induction heating, you must first understand its fundamental mechanism. The process is a direct application of electromagnetic principles.

The Electromagnetic "Engine"

An induction heating system's power supply sends a high-frequency alternating current (AC) through an inductor, which is typically a copper coil. According to Maxwell's equations, this alternating current creates a powerful and rapidly changing magnetic field in the space around the coil.

Inducing "Eddy" Currents

When a conductive workpiece, such as a metal part, is placed within this magnetic field, the field induces circular electrical currents inside the part. These are known as eddy currents.

Resistance and Hysteresis Generate Heat

Heat is generated in two ways. First, the material's natural electrical resistance opposes the flow of these eddy currents, resulting in intense localized heating (Joule effect). Second, if the material is magnetic (like iron), the rapid reversal of its magnetic domains creates additional frictional heat through hysteresis. This is why magnetic materials often heat faster than non-magnetic ones.

The Four Pillars of Control

Mastering induction heating means manipulating four key variables to achieve a desired outcome. These factors do not work in isolation; they are deeply codependent.

Pillar 1: Material Characteristics

The properties of the workpiece itself are the starting point for any induction process.

- Resistivity: Materials with higher electrical resistivity heat more efficiently. The resistance is what converts the induced current into heat.

- Magnetic Permeability: Magnetic materials are highly susceptible to induction heating below their Curie temperature, benefiting from both eddy currents and hysteresis losses.

- Size and Geometry: The thickness and shape of the part dictate how it will interact with the magnetic field.

Pillar 2: Power Supply and Frequency

The power unit मौसम a solid-state RF supply—is the heart of the system, and its settings are your primary controls.

- Power (kW): The power level determines the rate of heating. More kilowatts deliver more energy per second, causing the part's temperature to rise faster.

- Frequency (kHz): The frequency of the alternating current determines the depth of heat penetration. This is a critical concept known as the "skin effect."

High-frequency currents (>100 kHz) remain on the surface of the part, creating a shallow heat zone. Low-frequency currents (<10 kHz) penetrate deeper into the material's core.

Pillar 3: Inductor (Coil) Design

The inductor is a custom-shaped copper coil that creates and shapes the magnetic field. Its design is arguably the most critical factor for precision heating.

The coil's geometry—its shape, size, and number of turns—determines where the magnetic field is strongest. This focuses the energy, allowing you to heat a specific area, like the teeth of a gear or the tip of a shaft, without affecting the rest of the part.

Pillar 4: Coupling Efficiency

Coupling refers to the proximity of the inductor to the workpiece. The strength of the magnetic field diminishes rapidly with distance.

Therefore, a closer distance between the coil and the part results in a more efficient transfer of energy and a more intense heating effect. Inconsistent spacing can lead to uneven heating and unreliable results.

Understanding the Trade-offs

Optimizing an induction process always involves balancing competing factors. There is no single "best" setting, only the right combination for a specific goal.

Depth vs. Speed

To heat the core of a large part, you need a low frequency to ensure deep penetration. However, this process can be slower. To harden a surface, you need a high frequency for shallow, rapid heating, but this will leave the core unaffected.

Efficiency vs. Flexibility

A custom-shaped coil that is perfectly coupled to a specific part will be extremely efficient. However, a more generic, multi-turn helical coil might be less efficient but far more versatile, able to heat parts of various sizes. The choice depends on production volume and part variety.

Power vs. Cost

A high-power supply will heat parts faster, increasing throughput. However, it comes with a significantly higher capital investment and greater energy consumption. The optimal power supply is one that meets the required production rate without being oversized.

How to Apply This to Your Process

Your application dictates how you should prioritize these factors.

- If your primary focus is surface hardening: You will need a high-frequency power supply and a coil designed for close coupling to create a shallow, rapid heat zone.

- If your primary focus is through-heating a large billet for forging: You will require a low-frequency system with sufficient power to penetrate deep into the material's core.

- If your primary focus is precision brazing or bonding: The design of the inductor is paramount to concentrate heat only on the joint area, often using a medium-to-high frequency.

- If your primary focus is heating very thin or small parts: A very high frequency is necessary, as a lower-frequency magnetic field may pass through the part with insufficient interaction.

By understanding these interconnected factors, you can engineer an induction process that delivers precise, repeatable results for your specific manufacturing challenge.

Summary Table:

| Factor | Role in Induction Heating | Key Consideration |

|---|---|---|

| Material Properties | Determines heating efficiency and method (eddy currents, hysteresis). | Resistivity, magnetic permeability, part geometry. |

| Frequency & Power | Controls heat penetration depth (skin effect) and heating speed. | High frequency for surface heating; low frequency for deep core heating. |

| Coil Design | Focuses and shapes the magnetic field for precise heating zones. | Custom geometry to target specific areas like gear teeth or joints. |

| Coupling Efficiency | Affects energy transfer intensity and heating uniformity. | Closer distance between coil and part yields more efficient, intense heating. |

Ready to engineer a precise and efficient induction heating process for your application?

Whether your focus is surface hardening, through-heating for forging, or precision brazing, the right equipment is critical. KINTEK specializes in high-performance lab equipment and consumables, including induction heating systems tailored to your specific material and geometric challenges.

Contact our experts today to discuss how we can help you optimize your heating parameters for superior control, repeatability, and results.

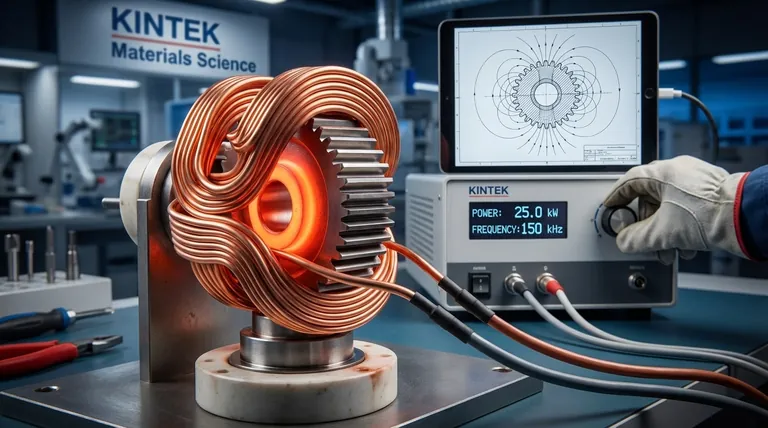

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What are silicon carbide heating elements used for? Reliable High-Temp Heating for Industrial Processes

- What is SiC melting point? Discover the Extreme Thermal Stability of Silicon Carbide

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments