Toggle Categories

Get Instant Support

Choose your preferred way to connect with our team

-

Get Free Quote Fill out form for detailed pricing

-

Send Email Detailed inquiry support

-

WhatsApp Quick mobile chat

Response Time

Within 8 hours on working days, 24 hours on holidays

Sample Preparation

KinTek sample preparation equipment includes sample crushing,milling, as while as while sieving equipment, hydraulic press equipment includes manual press, electric press, isostatic press, hot press and press filtering machine.

Thermal Equipment

KinTek supplies a broad range of high-temperature furnaces, including lab, pilot production, and industrial production furnaces, with a temperature range of up to 3000 ℃. One of KinTek's advantages is the ability to create custom-made furnaces tailored to specific functions, such as different heating methods and speeds, extra high and dynamic vacuums, controlled atmospheres and gas circuits, automated mechanical structures, and software and hardware development.

Lab Consumables & Materials

KinTek offers a range of lab consumables and materials, including evaporation materials, targets, metals, electrochemistry parts, as well as powders, pellets, wires, strips, foils, plates, and more.

Bio-Chem Equipment

KinTek bio-chem equipment comprises rotary evaporators, glass and stainless steel reactors, distillation systems, circulating heaters and chillers, as well as vacuum equipment.

Products

Laboratory High Throughput Tissue Grinding Mill Grinder

Item Number : KT-MT

Manual button battery sealing machine (digital display)

Item Number : PC2NS

Manual button battery sealing machine

Item Number : PC2N

Laboratory Micro Horizontal Jar Mill for Precision Sample Preparation in Research and Analysis

Item Number : KT-XRD180

High Energy Planetary Ball Mill Milling Machine for Laboratory

Item Number : KT-P2000

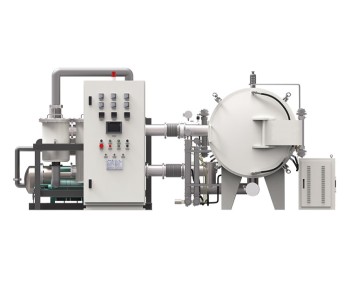

Vacuum Heat Treat Sintering Brazing Furnace

Item Number : KT-BF

Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

Item Number : TPM-01

915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

Item Number : MP-CVD-101

HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

Item Number : MP-CVD-100

High Energy Vibratory Ball Mill for Lab Use

Item Number : KT-BM500

Hybrid High Energy Vibratory Ball Mill for Lab Use

Item Number : KT-BM400

Laboratory Grinding Mill Mortar Grinder for Sample Preparation

Item Number : KT-MG200

High Energy Vibratory Laboratory Ball Mill Double Tank Type

Item Number : KT-VB200

High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

Item Number : KT-VB100

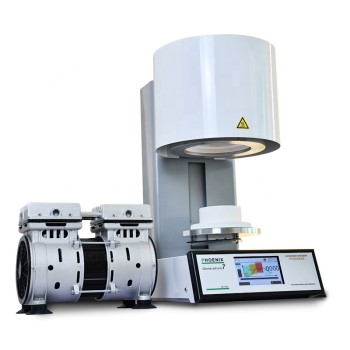

Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

Item Number : KT-DS10

Laboratory Hybrid Tissue Grinding Mill

Item Number : KT-MT20

Disc Cup Vibrating Mill Multi-Platform for Lab

Item Number : KT-DVMP

Laboratory Disc Cup Vibratory Mill for Sample Grinding

Item Number : KT-DVM

Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

Item Number : KT-T200TAP

Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

Item Number : KT-VD200

Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

Item Number : KT-VM200

Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

Item Number : KT-V200

High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

Item Number : KT-P4000H

High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

Item Number : KT-P4000E

High Energy Planetary Ball Mill Milling Machine for Laboratory

Item Number : KT-P4000

Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

Item Number : KT-CPBM

High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

Item Number : KT-P2000H

High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

Item Number : KT-P2000E

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Articles

The Thermodynamics of Silence: How Inert Gas Breaks the Vacuum Barrier

In high-temperature vacuum furnaces, cooling is an aggressive, engineered process. Learn how inert gas acts as a thermal conveyor belt to control metallurgy.

Why Your Compacted Parts Fail: The Hidden Flaw Your Sintering Furnace Can't Fix

Struggling with inconsistent powder-pressed parts? The real flaw isn't your furnace. Learn how Cold Isostatic Pressing ensures flawless results.

Your Tungsten Furnace Is Failing. The Culprit Isn't What You Think.

Frustrated with contaminated samples from your tungsten furnace? Discover the hidden cause—and how mastering the atmosphere unlocks reliable results.

The Invisible Architecture of Precision: Mastery Before the Current Flows

Achieve electrochemical accuracy by mastering the four pillars of preparation: rigorous inspection, cleaning, installation, and electrolyte management.

The Thermal Ceiling: Pushing 2200°C in Vacuum Environments

Discover how specialized vacuum furnaces achieve 2200°C+ through advanced graphite and tungsten elements. A deep dive into thermal engineering and material limits.

Why Your Induction Furnace Melts Are Failing: The Critical Mistake Most Labs Make

Frustrated with inconsistent metal quality from your induction furnace? Discover the root cause and learn how to choose the right equipment.

Why Your High-Temperature Furnace Fails: It’s Not About the Max Temp

Struggling with inconsistent results from your vacuum furnace? Discover why chasing the highest temperature is a costly mistake and how to fix it.

The Quiet Physics of Purity: Mastering Heat in a Vacuum

Vacuum furnaces don't just heat; they fundamentally alter physics by replacing convection with radiation. Explore how removing air unlocks material perfection.

The Hidden Reason Your Powder Metallurgy Parts Keep Failing (And It’s Not Your Furnace)

Tired of cracked sintered parts? The problem isn't your furnace. Learn the real root cause—uneven density—and how Cold Isostatic Pressing fixes it.

The Engineering of Nothingness: Why Absolute Purity Requires a Vacuum

Discover why vacuum furnaces are indispensable for high-stakes thermal processing. We explore the balance between material integrity and oxidation control.

Why Your Furnace-Brazed Parts Fail—And Why It's Not the Furnace's Fault

Discover the real reason your furnace brazing results are inconsistent and costly. It's not the equipment; it's a misunderstanding of physics.

The Architecture of Emptiness: Why High-Stakes Engineering Demands a Vacuum

Vacuum furnaces are not just hotter ovens; they are tools of subtraction. Discover how removing the atmosphere unlocks material perfection in aerospace and medicine.

Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?

Your vacuum furnace reaches temperature but ruins your parts? Learn the hidden cause of failure and how choosing the right hot zone material ensures perfect results.

The Geometry of Cleanliness: Why Surface Integrity Defines Electrochemical Success

Master the art of electrolytic cell maintenance. Discover how a tiered cleaning protocol prevents contamination and ensures experimental reproducibility.

The Art of Nothingness: Precision and Purity in Vacuum Heat Treatment

Discover the engineering logic behind vacuum furnaces. Learn how eliminating air prevents oxidation, ensures purity, and enables advanced metallurgy.

Why Your Brazed Joints Are Inconsistent—And the Fix Isn't in the Furnace

Frustrated by inconsistent brazed joints? Discover the hidden cause of failure that isn't heat or filler, and learn how to fix it for good.

The Thermal Divide: Navigating the Choice Between Tube and Chamber Furnaces

A guide to the trade-offs in vacuum heating. We explore how physical scale and maximum temperature dictate the choice between tube precision and chamber capacity.

Why Your Heat Treatment Fails: Beyond the Maximum Temperature of Your Vacuum Furnace

Discover why focusing on max temperature leads to failed heat treatments. Learn to match your vacuum furnace to your process for consistent, high-quality results.

The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

Discover why the absence of air is the key to metallurgical perfection. We explore the physics, the trade-offs, and the precision of vacuum heat treatment.

The Real Reason Your Sintered Parts Crack (And It’s Not the Furnace)

Stop blaming the furnace. Discover the hidden flaw in powder pressing that causes parts to crack and learn how Cold Isostatic Pressing (CIP) offers a permanent fix.